Pipe Beveling Equipment

Engineered for Speed. Built for Precision.

Precision Beveling Starts with the Right Tool

At SEC, we supply industry-proven pipe beveling systems designed to meet the highest demands in field and shop environments. Our ESCO end-prep tools deliver fast, consistent results—no matter the jobsite.

From portable handheld units to robust split-frame machines, we offer the complete ESCO lineup including Wart Millhog, Prepzilla Millhog, C-Hog Millhog, Mongoose Millhog, and more. Each tool is engineered for clean cuts, smooth bevels, and easy repeatability—with minimal training or downtime required.

Not sure which system fits your workflow? Our team can walk you through the options and help spec the right gear for your exact pipe diameter, wall thickness, and application.

Built for Tough Jobs

From power plants to fabrication shops, our ESCO tools are made to perform in high-demand settings with durable construction and ergonomic design.

Cut with Confidence

Achieve uniform bevels with minimal chatter or distortion—even on alloy, stainless, and high-pressure pipe.

Plug In & Go

Quick setup. Minimal maintenance. Repeatable performance that scales with your team’s workload.

Pipe Beveling Equipment We Offer

SEC supplies industry-proven pipe and tube beveling tools designed for clean cuts, consistent results, and high-performance operation in demanding environments.

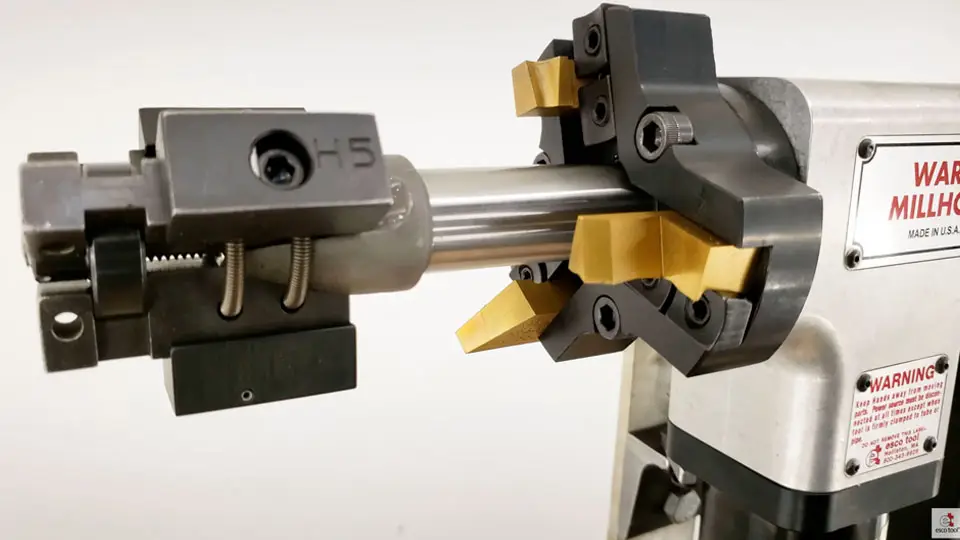

Wart Millhog

The Wart Millhog is a portable right angle I.D. clamping pipe and tube beveling machine that features an efficient low maintenance design. Incorporating a gear drive that is fully supported by dual opposed tapered roller bearings and three heavy duty ball bearings. This gives the Wart the backbone to satisfy a wide variety of applications and is a favorite choice among boilermakers and pipe fitters. All components are made of the finest materials and parts subject to wear are heat treated for durability and long use. Sealed construction prevents debris from getting inside the tool, allowing use in any orientation. What’s more the compact design requires a minimum of 2.625″ to fit between tubes in a boiler tube waterwall.

- Narrow body 2.625″ (66.7mm)

- Bevel, face and bore simultaneously

- Interchangeable pneumatic and electric motor options

- Patented clamp system, allows the clamps to release from a tube as easily as they tighten

- Heavy duty ratchet wrench and knurled knob allows easy clamping and is perfect for limited access area

- Bevel, face and bore simultaneously

- Mounts ridgidly to produce a clean, continuous chip

- Lightweight and requires no special training

- Rugged dual-opposed tapered roller bearings support the gear drive for non-stop operation

- EscoLock cutter blade holding system reduces vibration and maximizes the number of preps per blade

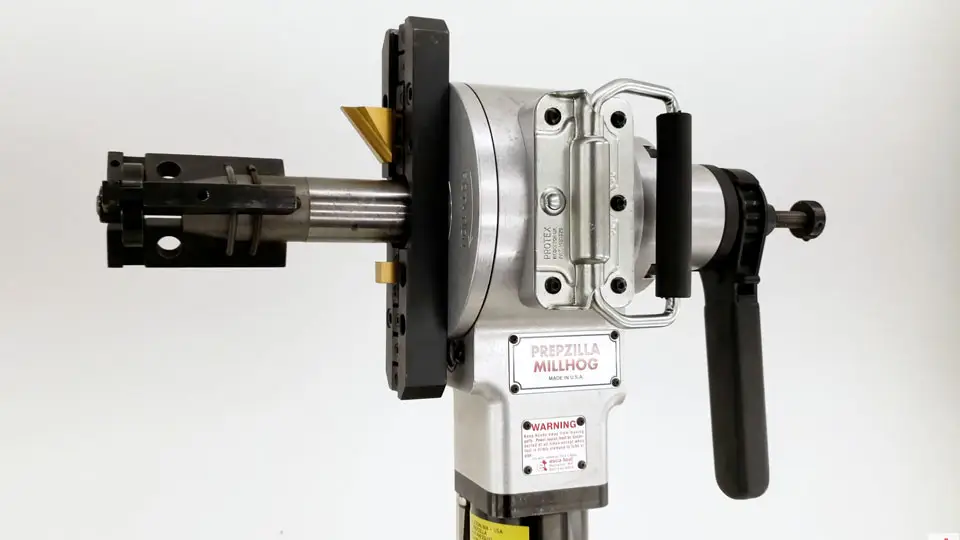

Prepzilla Millhog

The Prepzilla Millhog is smooth, quiet and powerful. It is highly desired for its ability to bevel difficult pipe alloys like super duplex and P-91 quickly and efficiently. Ruggedly designed for years of trouble free service, the Prepzilla is built with dual opposed tapered roller bearings, heat treated and hardened clamping, cutting and operational components. It can bevel pipe at any angle without cutting fluid for fast fit-up and enables precise pipe joint welds.

- Only 1 mandrel and 8 sets of clamps to cover the entire range of the tool

- Third cutter blade tool post expands pipe beveling capacity for beveling, facing and boring simultaneously

- Low rpm and tremendous torque

- Produces thick chips on all highly alloyed tube and pipe without cutting fluids

- Pneumatic and electric motor choices are easily interchangeable

- Dual opposed tapered toller bearing construction delivers rock solid performance

- Heavy duty clamping system will not break

Mongoose Millhog

The Mongoose MILLHOG is a torque free beveling machine for tube and pipe from 0.625” (15.9mm) I.D. to 3.0” (76.2 mm) O.D. and is only 2.25” (57.15 mm) wide which makes it ideal for power station boiler tube work and constrained situations with limited access. Featuring a patented push-pull clamp and release mechanism, it allows the clamps to release from a tube as easily as they tighten. Ideal for beveling, facing and boring on a wide range of tube and pipe alloys, the Mongoose has dual opposed tapered roller bearing and employ the rigid EscoLock blade locking system; which provides chatter-free performance and produces a thick chip without cutting fluids.

- Narrow body 2.25″ (27.15mm)

- Lightweight and torque-free

- Interchangeable pneumatic, electric and battery motor options

- Patented clamp system, allows the clamps to release from a tube as easily as they tighten

- Permanently attached wrenches

- Bevel, face and bore simultaneously

- Rugged dual-opposed tapered roller bearings support gear drive for non-stop operation

- EscoLock blade holding system reduces vibration and maximizes the number of preps per blade

C-Hog Millhog

The C-Hog Millhog beveling machine securely attaches to the tube O.D. with a huge clamp that minimizes chatter and vibration and is well suited for small-bore tubes because there is no I.D. clamp or mandrel to interfere. The I.D. clearance gained also allows for large, tough I.D. boring blades that increase Cutter Blade endurance. Designed for maximum operator comfort, efficiency, and ease of use, the C-Hog’s attached feed wrench lets the operator comfortably feed the tool as it bevels the tube with minimal fatigue. Constructed to deliver reliable performance on the toughest applications, the C-Hog is a rugged tool that is lightweight and compact. Highly engineered, it incorporates state-of-the-art materials and heat-treated components.

Using the Millhog pipe beveler is easy and efficient and can help operators achieve accurate results on all materials, including stainless steel, alloy steel, and more. The C-Hog’s rapid feed rate saves time and offers a quality bevel that meets the highest standards. Feel free to contact us for more information on the C-Hog Millhog and learn how it can help you get the job done.

- Narrow body 1.75″ (44.45mm)

- Large clamping surface rigidly holds tool for chatter-free bevels

- Powerful pneumatic, electric, and battery motor options

- No I.D. mandrel makes the C-Hog perfect for boring

- Robust wrenches are securely attached

- Changing clamps and other tooling is easy

- Low maintenance

- Compact, lightweight, and rugged

Tube Rolling Motors

ESCO Tool Tube Rolling Motors and Tube Expanders are used for fabricating and maintaining boilers, heat exchangers, and condensers. Our rolling motors come in a variety of torque options and have capabilities of performing both straight and flared rolls for the most accurate and tightest bond to the tube sheet. Like all of ESCO Tool’s rental equipment, every tool/machine is completely taken apart, scrubbed clean, reassembled and tested after every job it is on. Tube rolling motors are set up on our torque testing unit to assure the highest level of functionality before they make it to your site.

Understanding the material you are working with, its thickness, and its circumference is essential for any boiler tube rolling motors or expanding task. That’s why the team at SEC Automation Inc provides our customers with the expertise they need to ensure a successful outcome. We understand how important it is for each job to be done right and on time, so we strive to make sure each of our machines works perfectly.

SEC Automation is here to provide you with top-quality professional equipment for pipe fabrication, machining, and maintenance. We know that our hard-working clients deserve equipment that works even harder. If you need to purchase or rent tube rolling motors and tube expanders, SEC Automation has your back. We carry both boiler tube rolling motors and heat exchanger tube rolling motors to suit all your industrial needs.

- Quickly and automatically control tube expansion

- Precise, consistent tube wall reduction and tight tube joints

- Torque control prevents over and under expansion

- Pneumatically powered

- Flare and straight rolls

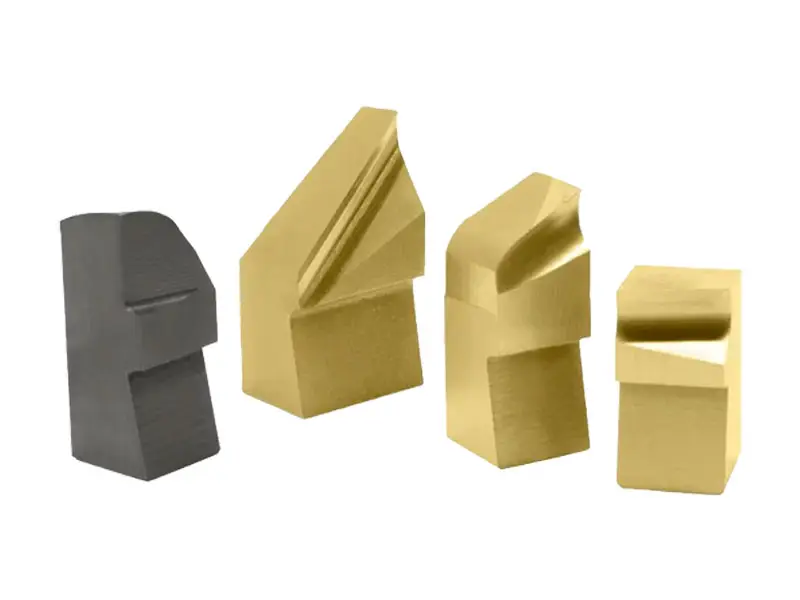

M-Series Blades

Pipe beveling machine blades are strategically designed to cut pipes by material and machine type. These M-Series blades custom-fit specific MILLHOG beveling machines, including the Terminator, Dictator I and II, Commander, Wart, Mini, and Prepzilla. The high-quality design of these cutting blades creates a consistent production of clean, weldable pipe ends in one thorough process.

SEC Automation supplies M-Series blades for our customer’s industrial applications. We pride ourselves on offering the latest and greatest beveling and welding products in the industry. Designed with the end-user in mind, you can count on these specialty cutting-edge blades for their durability, longevity, and tried-and-tested heat resistance. Contact the SEC team with any further inquiries, or request a quote with us today.

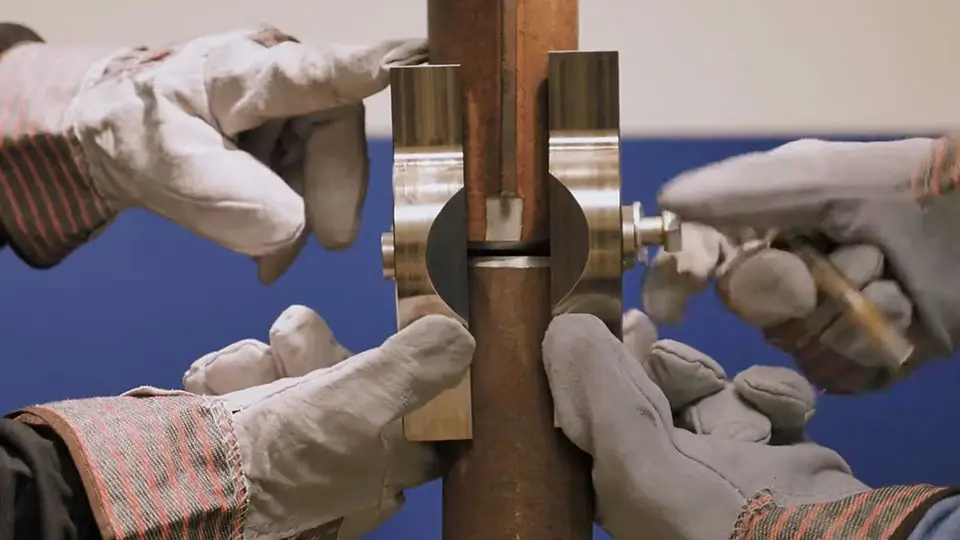

Hog Tie Boiler Tube Clamp

The Hog Tie boiler tube joint alignment clamp tool speeds up the welding process for boiler tube waterwall panel replacement. In preparation for creating welded tube joints, this innovative product quickly and accurately aligns new boiler tube ends with existing tubes. Accurate tube alignment helps establish a better-welded tube joint, reducing the risk of tube joint failure due to inaccurate alignment. Overall, this saves time and money on costly boiler shut-down and re-work.

- Align tube ends quickly for tube joint tack welding

- Ideal for waterwall, economizer, header, crossover, superheat, reheat, and generating tubes

- Speeds boiler tube waterwall welding process

- Reduces the risk of costly tube joint failure due to misalignment\

- Safety Lanyard easily connects clamp halves for fall protection

- Made of high strength precision machined steel for long service

- Replaceable threaded inserts

- Available kits come with everything needed

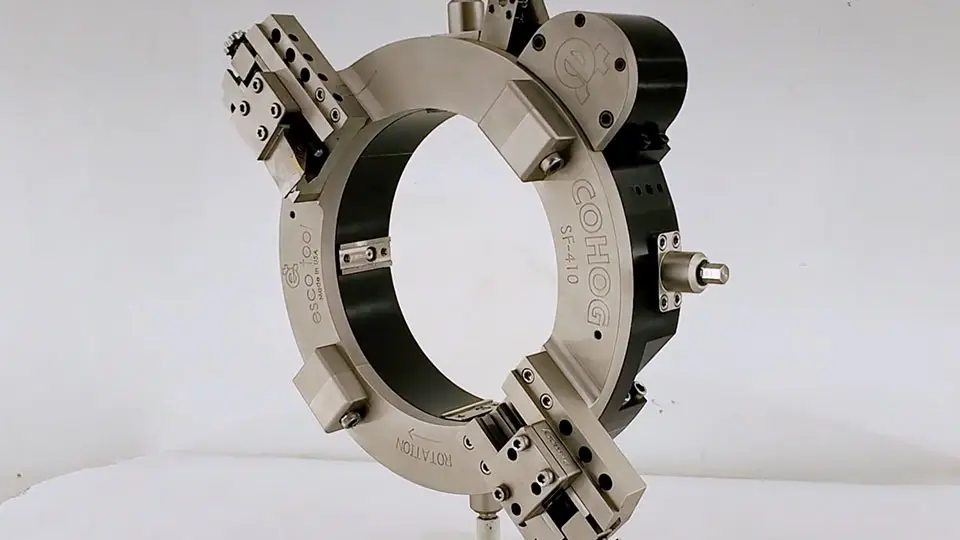

Clamshell Split Frame Tool

For decades, ESCO Tool has manufactured rugged, reliable and simple to operate tube and pipe fabrication equipment known to the industry as MILLHOG®. Years of working closely with end-users, has led us to develop our own line of split frame machines that hold true to our name. The all new COHOG® split frame eliminates the complication associated with traditional OD mounted tube and pipe fabrication machines while setting a new standard for lasting performance.

At the core of the COHOG® is its uniquely built frame. The stationary ring is machined out of 7075 aluminum alloy, the strongest aluminum obtainable, and hard coated for maximum strength and durability. A full complement of precision-tuned eccentric bearings fully support the rotating ring which is machined from a custom steel forging, heat-treated and nickel-plated for long-lasting corrosion and wear resistance. Self-squaring clamp legs quickly align and secure the machine to the pipe making it rigid enough to part and bevel heavy wall pipe, in one operation, without vibration or chatter. COHOGs feature indexable tool slides and trip mechanisms that use a marked locating system to precisely align and quickly attach without shims or guesswork. A variety of blade modules easily attach to the tool slides and can hold conventional high-speed tool steel blades or cutting inserts. Most cutting inserts have multiple cutting edges, are simple to replace, and provide more cuts per blade at a lower cost.

- Rotating and stationary ring design makes the COHOG® extremely rigid for smooth cutting action on any material

- Components are built using the finest materials and hard anodized or nickel plated for superior corrosion resistance

- Sealed construction protects bearings and bearing races from cutting debris

- Indexable tool slides and trip mechanism use a marked locating system to make setup fast, easy and accurate.

- Modular tool slides use conventional tool steel blades or inserts with multiple cutting edges that proved more cuts per blade at a lower cost

- Full range of all tools is achieved with the internal clamp legs and single set of clamp extensions making mounting simple

- Powerful Pneumatic, Hydraulic and Electric motor options

- Available for sale or rent