Orbital welding is a specialized and precise technique essential in many industries, including aerospace, pharmaceuticals, and semiconductors. It involves the automated welding of tubes or pipes using a welding arc that rotates 360 degrees around a fixed workpiece. This method ensures consistent, high-quality welds, which are crucial for applications requiring stringent standards and minimal tolerance for error. Understanding the key components of orbital welding equipment is vital for those looking to leverage this advanced welding process effectively.

Let’s look at key components of orbital welding equipment and understand their functions in detail.

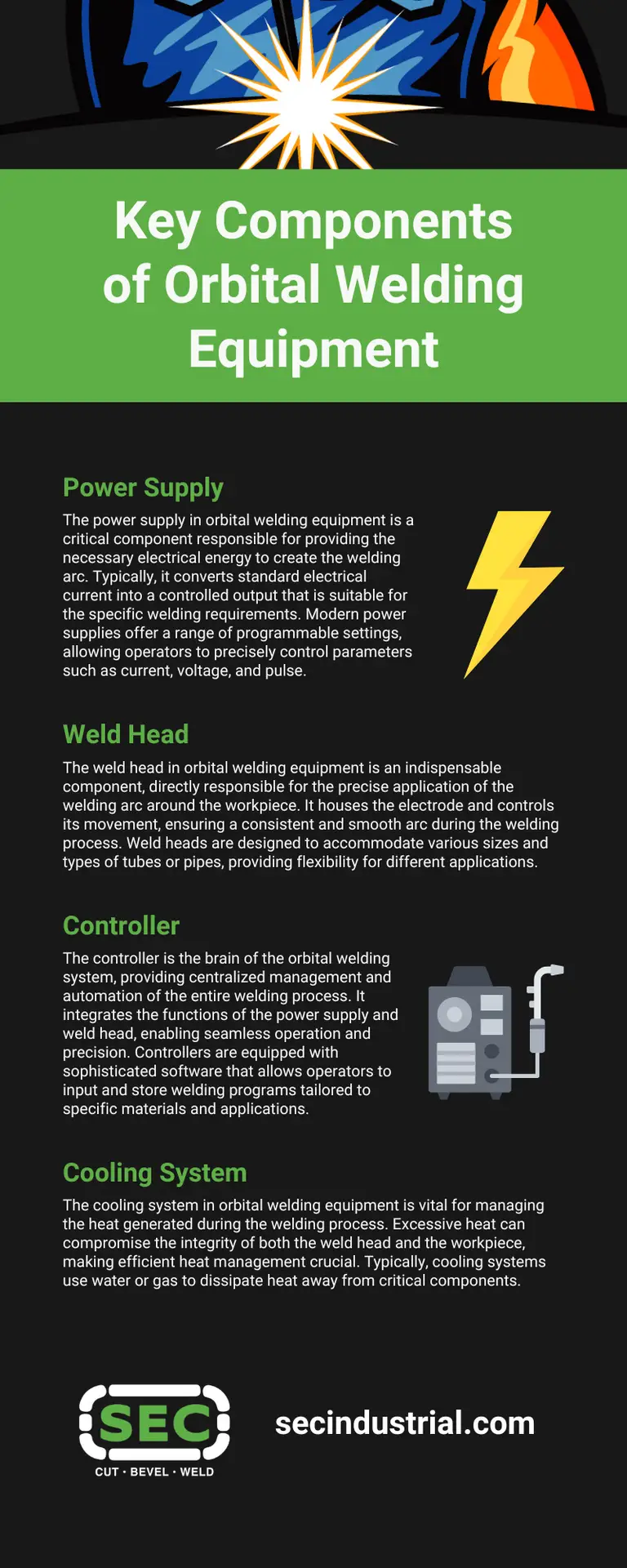

Power Supply

The power supply in orbital welding equipment is a critical component responsible for providing the necessary electrical energy to create the welding arc. Typically, it converts standard electrical current into a controlled output that is suitable for the specific welding requirements. Modern power supplies offer a range of programmable settings, allowing operators to precisely control parameters such as current, voltage, and pulse.

This level of control is essential for achieving the consistent and high-quality welds demanded by industries like aerospace and pharmaceuticals. Additionally, power supplies often come with integrated diagnostic tools that help monitor performance and ensure the welding process adheres to stringent quality standards. In essence, a reliable power supply is foundational for the success of any orbital welding operation.

Weld Head

The weld head in orbital welding equipment is an indispensable component, directly responsible for the precise application of the welding arc around the workpiece. It houses the electrode and controls its movement, ensuring a consistent and smooth arc during the welding process. Weld heads are designed to accommodate various sizes and types of tubes or pipes, providing flexibility for different applications.

They often feature advanced clamping mechanisms to secure the workpiece firmly in place, preventing any movement that could compromise the weld quality. Additionally, many modern weld heads come equipped with cooling systems to manage the heat generated during welding, thereby protecting the integrity of both the weld head and the workpiece. This meticulous control and adaptability make the weld head a crucial element for achieving high-quality orbital welds.

Controller

The controller is the brain of the orbital welding system, providing centralized management and automation of the entire welding process. It integrates the functions of the power supply and weld head, enabling seamless operation and precision. Controllers are equipped with sophisticated software that allows operators to input and store welding programs tailored to specific materials and applications.

This automation reduces human error and enhances the repeatability of welds, which is crucial for industries with high-quality standards. Advanced controllers also feature real-time monitoring and feedback systems, offering insights into parameters such as arc stability, weld temperature, and overall system performance. This data is invaluable for ensuring weld integrity and making necessary adjustments on the fly, thereby optimizing the welding process.

Cooling System

The cooling system in orbital welding equipment is vital for managing the heat generated during the welding process. Excessive heat can compromise the integrity of both the weld head and the workpiece, making efficient heat management crucial. Typically, cooling systems use water or gas to dissipate heat away from critical components.

These systems are designed with high efficiency to ensure that the temperature remains within optimal ranges, preventing overheating and potential damage. Advanced cooling systems are often integrated with the controller to provide real-time monitoring and adjustments, ensuring continuous operation without the risk of thermal distortion. By maintaining consistent temperatures, the cooling system helps achieve the high-quality, reliable welds necessary for demanding applications.

Weld Wire Feeder

The weld wire feeder is a crucial component in the orbital welding equipment, and it is responsible for delivering the filler material to the weld joint with precise control. It ensures a consistent feed rate, which is vital for achieving the desired weld characteristics and quality. Typically, weld wire feeders are designed to handle various types of welding wire, allowing flexibility for different materials and applications.

They come equipped with adjustable settings to control the speed and tension of the wire feed, which is crucial for maintaining a stable arc and preventing defects. Additionally, advanced weld wire feeders are integrated with the controller, offering synchronized operation that enhances the overall efficiency and accuracy of the welding process. This integration makes them indispensable for producing high-quality orbital welds.

Fixture or Clamping Device

The fixture or clamping device is an essential component in orbital welding equipment, designed to secure the workpiece firmly during the welding process. Its primary function is to prevent any movement that could compromise weld quality by ensuring the tube or pipe remains in a fixed position. Fixtures are often tailored to accommodate various sizes and shapes, offering versatility for different applications.

Advanced clamping devices include adjustable elements and quick-release mechanisms, enabling efficient setup and changeover between tasks. These features are crucial for maintaining alignment and consistency, especially in high-precision environments such as aerospace or semiconductor manufacturing. By providing stable support, the fixture or clamping device plays a pivotal role in achieving flawless, repeatable welds.

Remote Pendant

The remote pendant in orbital welding equipment provides operators with a user-friendly interface to control and monitor the welding process from a safe distance. This handheld device is equipped with buttons, dials, and often an LCD screen to display critical information such as welding parameters and system status. The remote pendant allows real-time adjustments to settings like current, voltage, and wire feed speed, offering immense flexibility during the welding process.

Its ergonomic design ensures that operators can make precise changes without interrupting the workflow, leading to smoother operations. Additionally, the remote pendant plays a crucial role in maintaining safety, as it minimizes the need for operators to be in close proximity to the high-heat welding environment.

Understanding the key components of orbital welding equipment is fundamental for anyone looking to leverage this advanced welding technique effectively. Each component—from the power supply and weld head to the controller, cooling system, weld wire feeder, fixture or clamping device, and remote pendant—plays an integral role in ensuring the precision, consistency, and quality of the welds. The synchronization of these elements enables industries with stringent quality standards to achieve superior results.

If you need orbital welding equipment, SEC Industrial offers a wide range of high-quality solutions to meet your needs. From power supplies and weld heads to controllers, cooling systems, and more, we have you covered. Contact us today for more information or assistance finding the right equipment for your needs.