Adopting automated pipe spool welding into your operations can improve workflow in several aspects. However, successful implementation requires strategic planning and a good understanding of your shop’s unique needs. Below are five tips for integrating automated pipe spool welding into your processes.

1. Assess Your Project Requirements

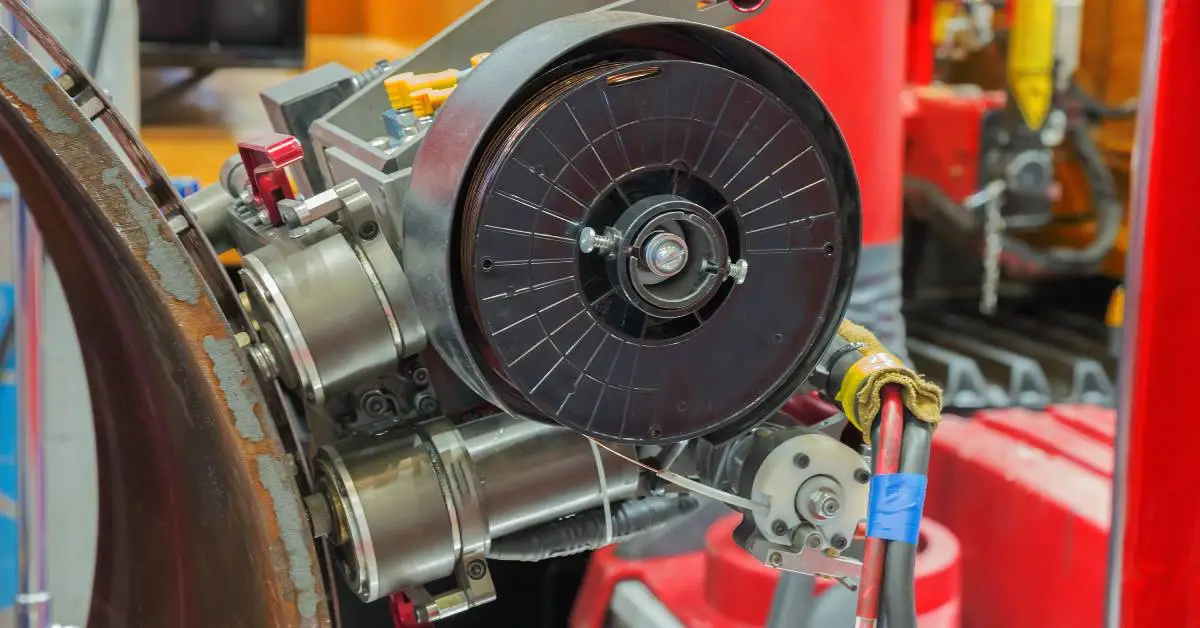

Before investing in equipment, determine your project’s specific welding needs. Consider factors like the type of material you’ll work with, as different metals may require specialized instruments, such as an M3 pipe spool welding machine.

The pipe diameter and wall thickness determine the appropriate equipment, as these dimensions can affect the welding process and the heat input required. The welding process itself, whether gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), or another method, also influences your choice. Fortunately, M3 is a versatile option for various applications.

Each process has unique requirements and capabilities. A clear understanding of these variables lays the foundation for proper integration into your workflows.

2. Optimize Shop Layout for Workflow Efficiency

The physical setup of your shop greatly impacts automation success. Position your welding system to minimize unnecessary movement of spools or personnel. Include designated areas for pipe preparation, staging, and post-weld inspection. This thoughtful layout reduces bottlenecks and maximizes the efficiency of automated workflows.

3. Train Your Workforce

Automation isn’t about replacing welders— it’s about enhancing their capabilities. Provide training on the M3 pipe spool welding machine’s operating procedures, maintenance, and programming.

Educating operators on how to troubleshoot common issues creates confidence and contributes to consistent output quality. Many manufacturers offer training programs, like those offered in collaboration with SEC Industrial, to simplify this process.

4. Incorporate Robust Monitoring Systems

Integrating automated pipe spool welding requires effective weld monitoring and quality control measures. Invest in systems that provide real-time tracking of welding parameters, such as amperage, voltage, and travel speed. This data enables early detection of anomalies, reducing rework and complying with industry standards.

5. Pilot the Technology

Rather than fully integrating automation at once, start with a pilot phase. Select a portion of your projects where automated welding can deliver visible advantages. This phased approach allows your team to adapt workflows and gain experience with the machine. You can also freely refine processes before wider implementation.

By following these five tips for integrating automated pipe spool welding, businesses can streamline operations without compromising weld quality or safety. From assessing project requirements to designing efficient shop layouts, these steps will guide you in optimizing workflows and improving productivity.