Pipe Spool Welding Machines

Precision for Every Pass. Power for Every Pipe.

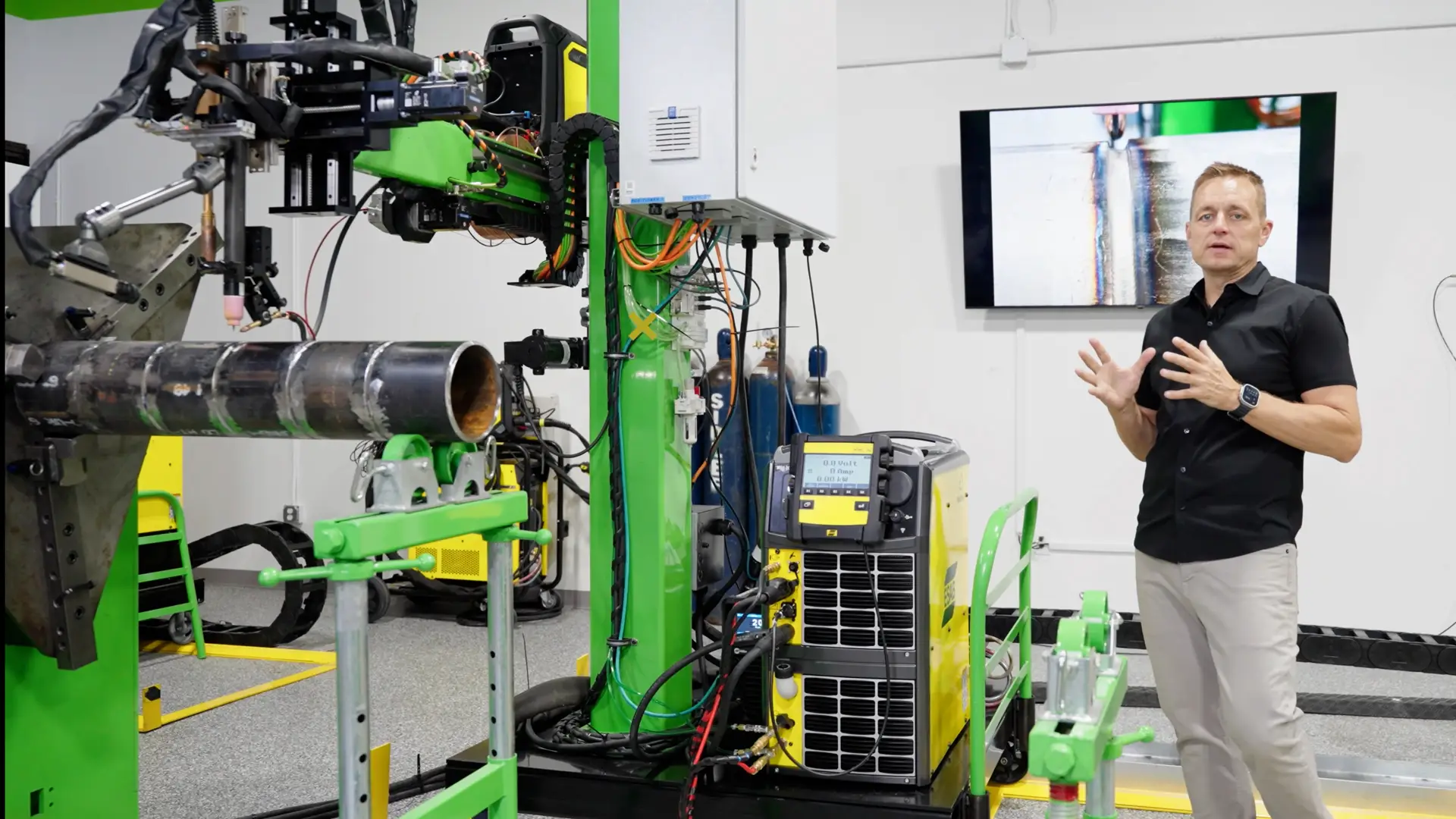

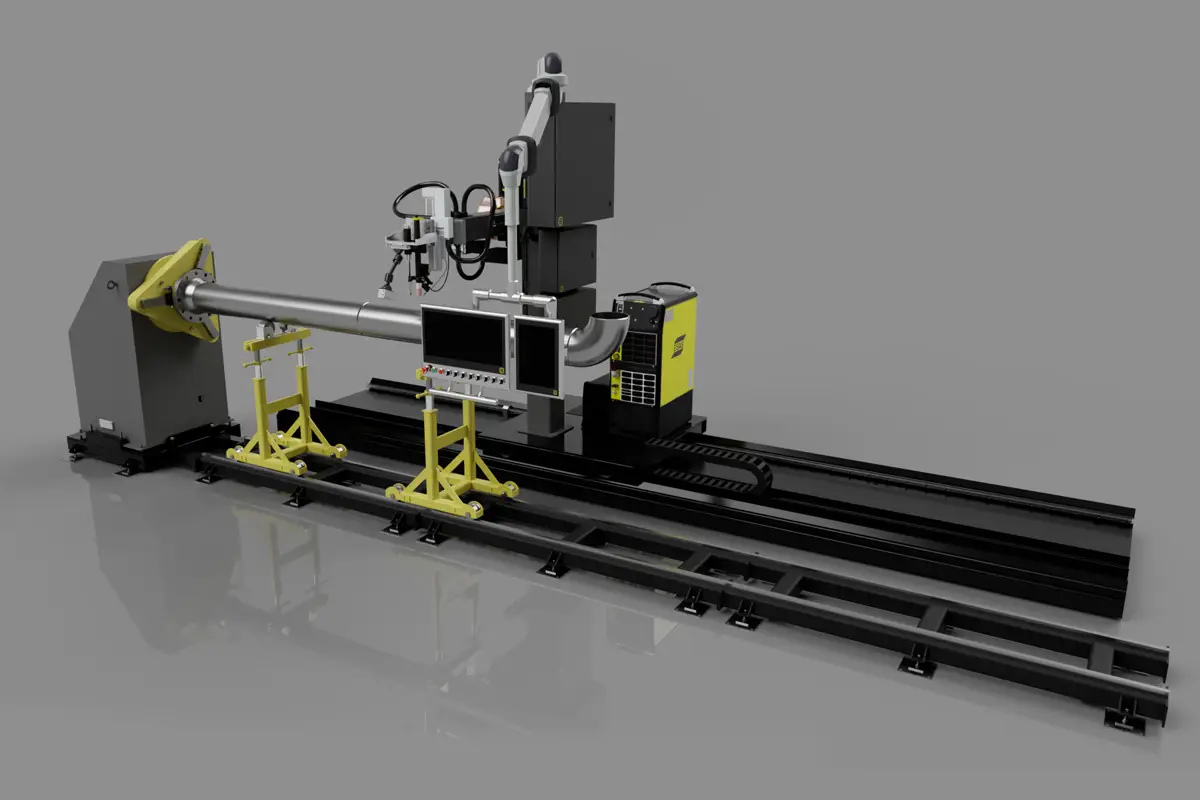

AutonoWeld M3: Built to Weld. Engineered to Perform.

AutonoWeld M3 Pipe Spool Welding Machine

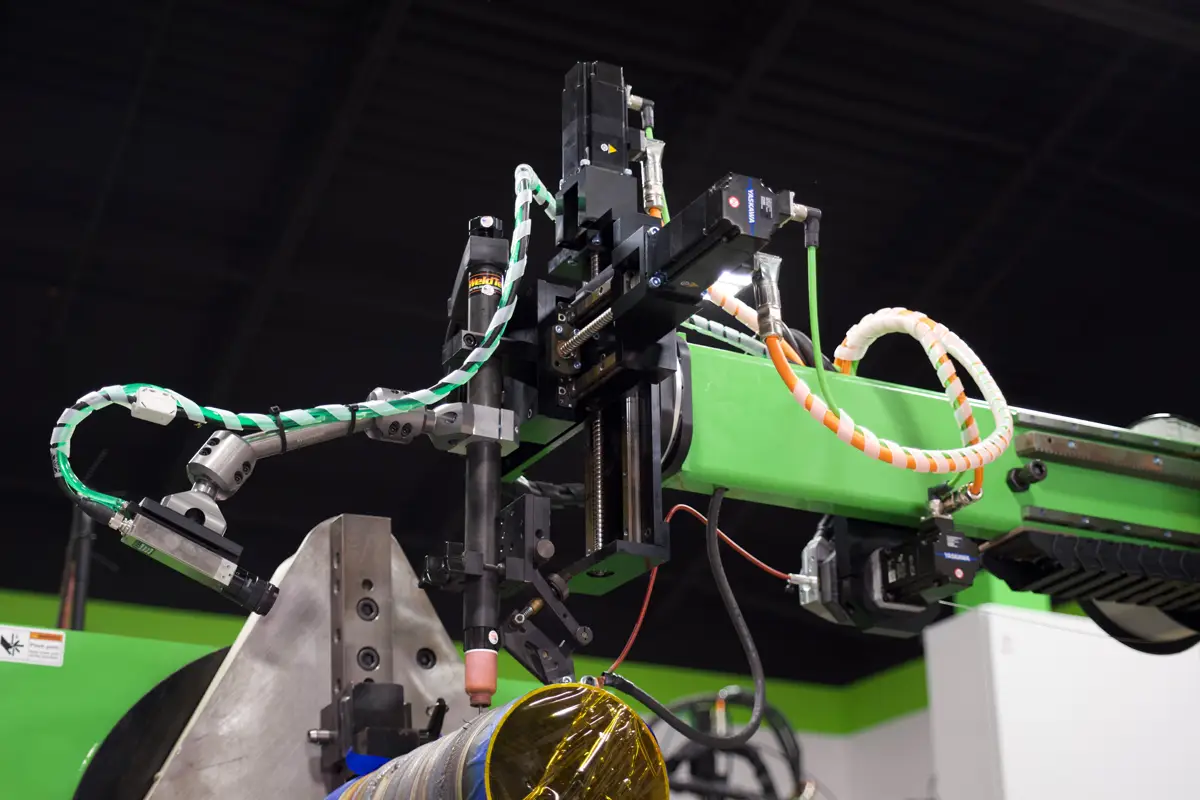

The AutonoWeld M3 is a fully automated, multi-pass welding system engineered for precision spool welding at scale. Built for performance and repeatability, it’s ideal for high-spec applications that demand tight tolerances and minimal rework.

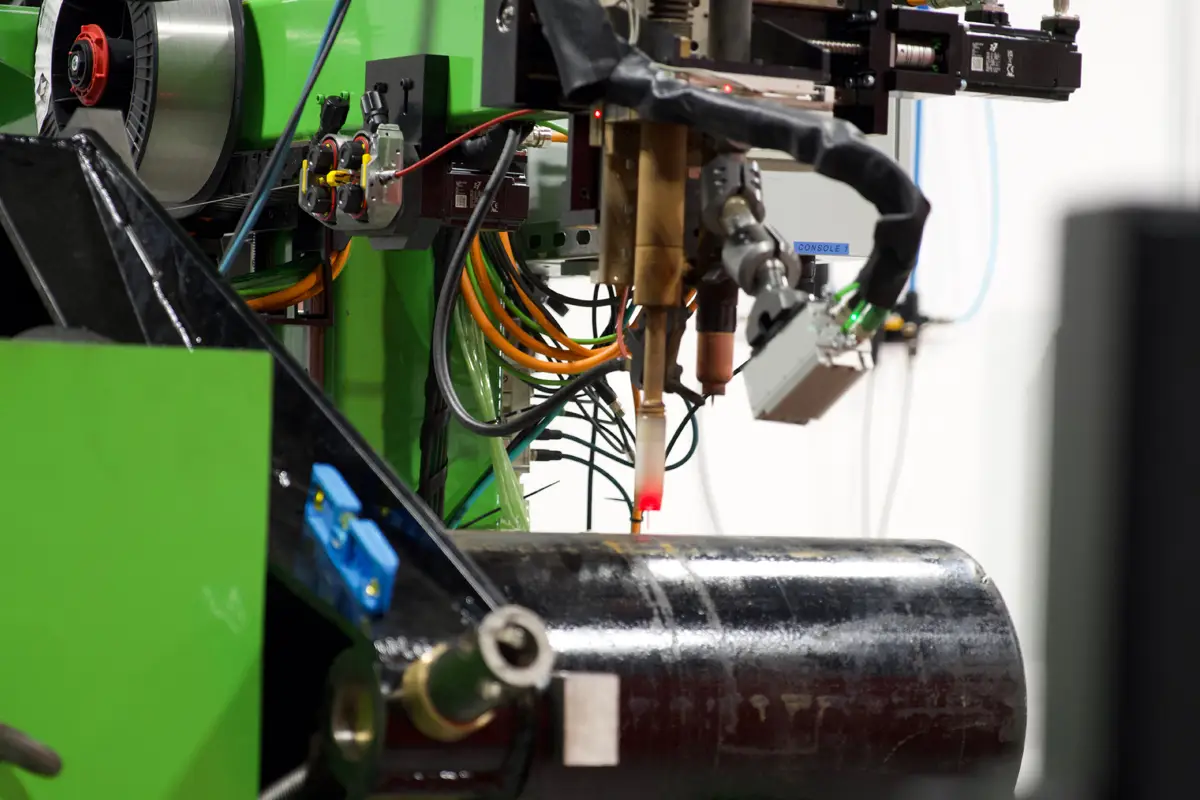

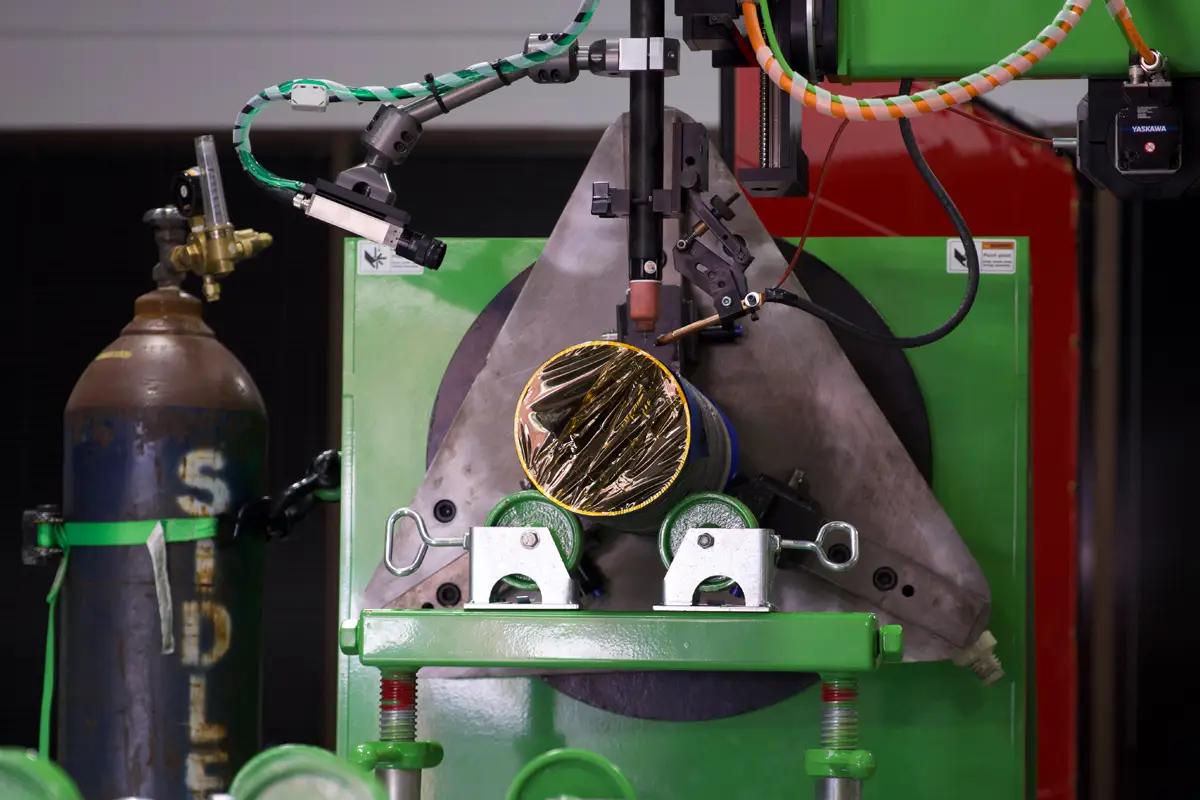

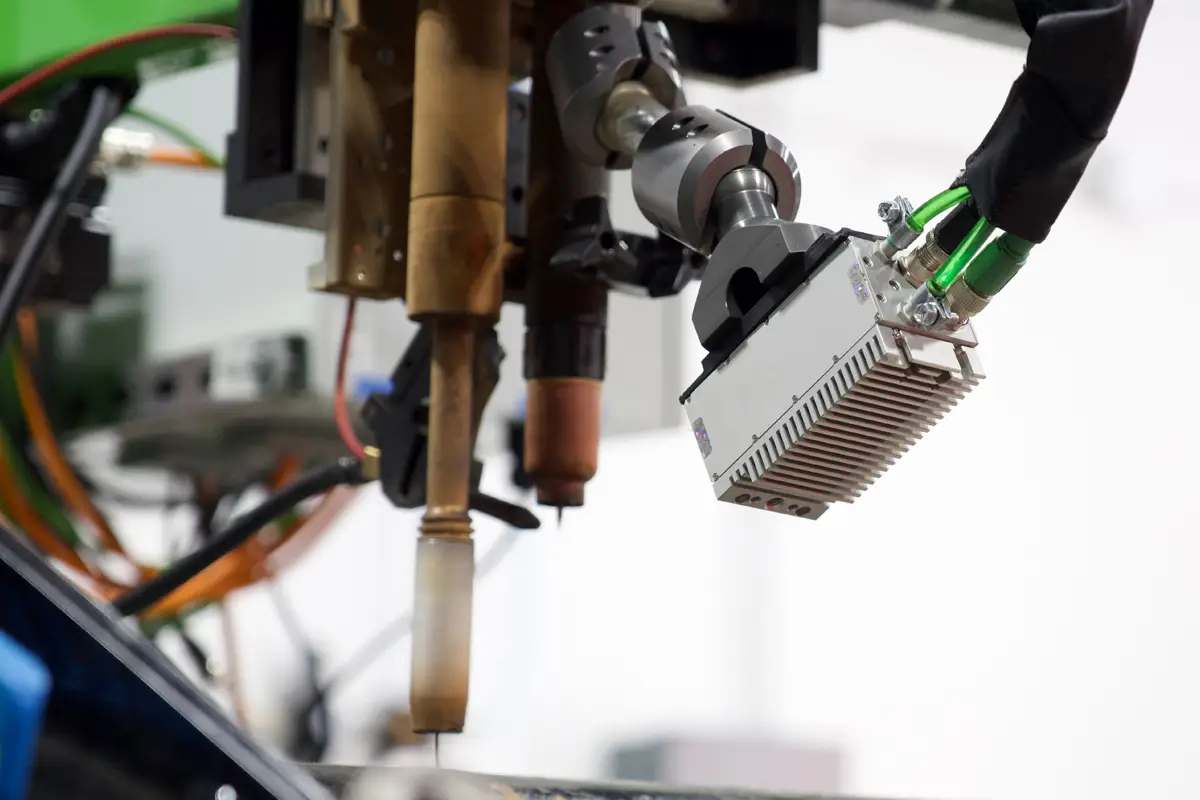

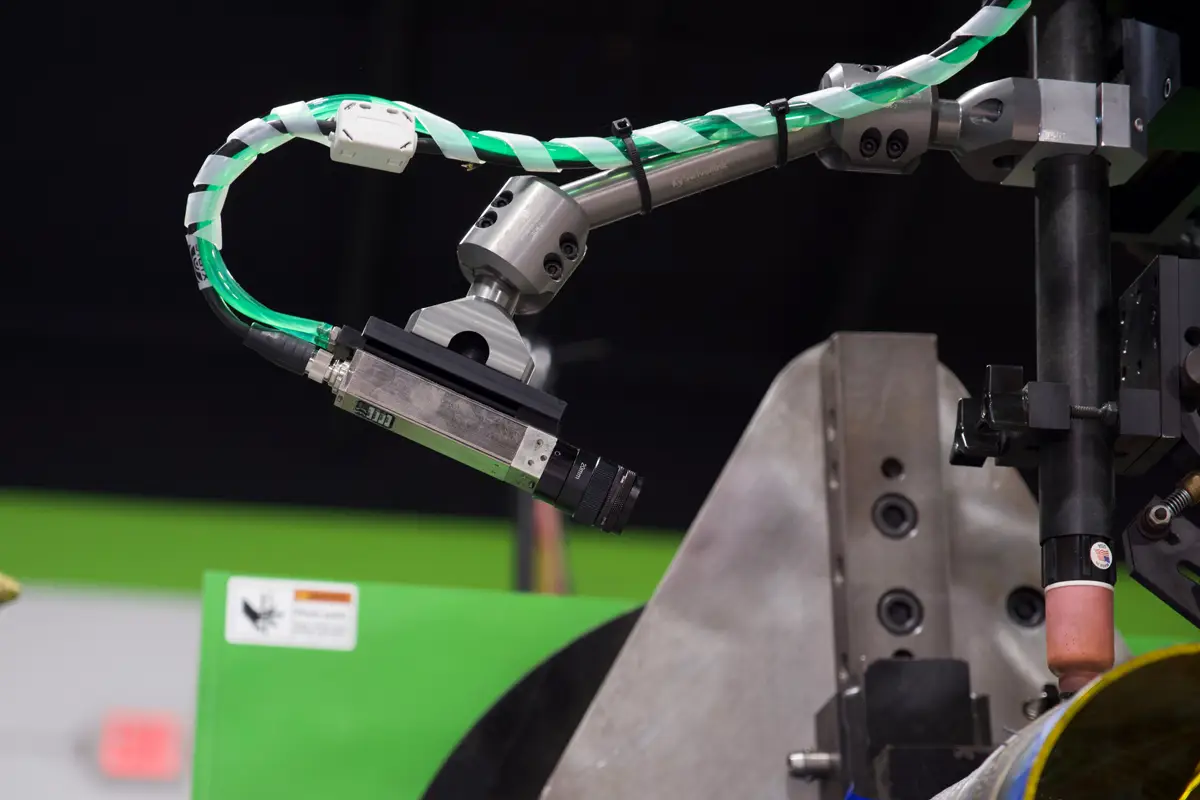

This system features integrated hotwire TIG, a programmable PLC touchscreen, and intelligent vision monitoring — all working together to deliver clean, consistent welds with low heat input and exceptional arc-on time.

From large-diameter pipe grippers to a 3000 lb. positioner and 20-foot cell length, the AutonoWeld M3 is built to move high volumes with minimal operator input. Whether you're fabricating for data centers, chilled water systems, or heavy industrial piping, this machine maximizes throughput and repeatability where it counts most.

Key Features

- ESAB Aristo 5000i Welding Package - precise setup and power source convenience in any job setting

- Cavitar Weld Vision System - specialized real-time weld monitoring, detection, and performance tracking

- AutonoWeld Hotwire System - unique technology to enhance overall weld speed, quality, and efficiency

- Training/Installation - Engineered for straightforward installation and intuitive operation, reducing training time and operator learning curves

Specifications

- 3000 lb and 6000 lb. positioners with pipe gripper

- Height-elevating manipulator with cross slides with 12” stroke

- PLC controlled with 15” touchscreen

- 25' 45' & 65' welding cell length options

- 2-36" diameter capacity

Video Walkthrough