The aerospace industry operates at the cutting edge of technology, continuously setting higher standards for precision, strength, and efficiency. One tool revolutionizing this field is autonomous welding, which combines advanced robotics with next-generation software to deliver unprecedented accuracy. At SEC Automation, we are proud to be part of this evolution, offering solutions that enhance aerospace quality while keeping customer needs front and center.

Why Precision Matters in Aerospace

Aerospace components experience extreme conditions, from intense heat and pressure to rapid atmospheric changes. This makes their structural integrity non-negotiable. Even the smallest flaw in a weld joint could compromise safety or performance. For manufacturers, achieving this level of quality demands the most sophisticated welding technologies available.

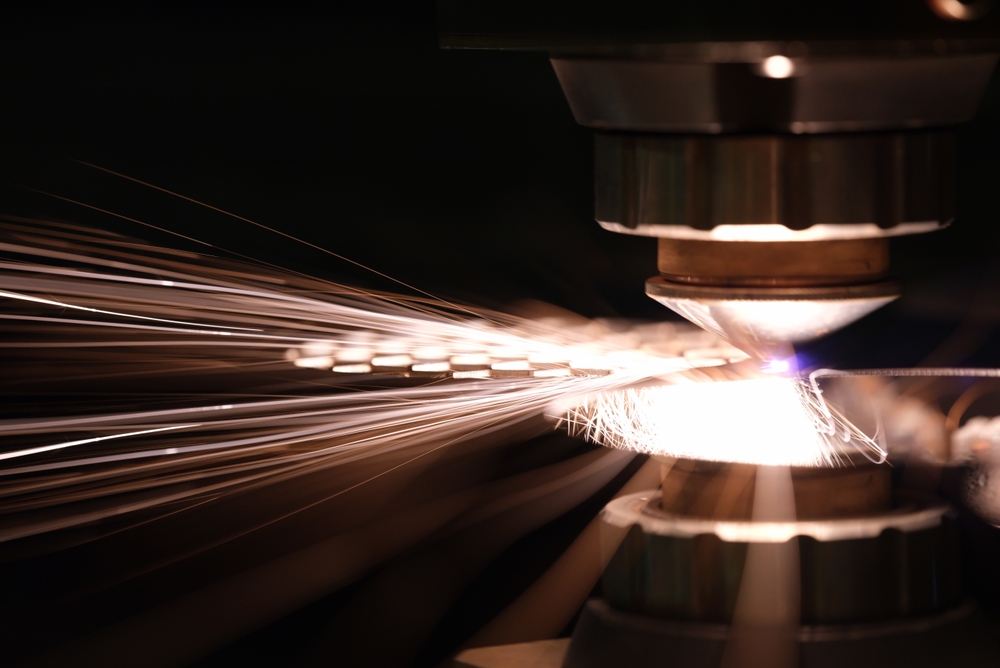

That’s where autonomous welding comes in. By automating critical welding tasks, this technology minimizes human error, ensures consistency, and delivers precision that meets even the most exacting aerospace standards.

The Advantages of Autonomous Welding

Superior Accuracy and Consistency

Autonomous welding systems excel in controlling parameters like heat, speed, and alignment. Unlike manual welding, robots can perform identical joints repeatedly without variations, ensuring uniformity across all components. At SEC Automation, we integrate real-time data monitoring into our automated systems, offering unmatched precision with minimal defects.

Time and Cost Efficiency

Efficiency is another advantage of autonomous welding. Traditional methods require skilled welders to manually complete each piece, often taking hours on intricate tasks. Meanwhile, autonomous machines work faster without sacrificing quality. This boosts productivity and reduces labor costs. For aerospace manufacturers balancing tight schedules, these savings are invaluable.

Enhanced Safety

Welding can expose workers to hazardous fumes, high temperatures, and risks associated with poor ventilation. Automation removes people from unsafe environments, reducing injuries and creating a safer workplace.

Innovations by SEC Automation in Aerospace Welding

At SEC Automation, our dedication to innovation drives us to deliver cutting-edge solutions tailored for aerospace applications. Here’s how we stand out:

- Next-Generation Robotics: Our autonomous welding machines are equipped with the latest robotics and software, ensuring seamless communication between components to optimize results.

- Flexible Solutions: Whether your project demands manual precision or the speed of automation, we offer options for both. Our manual welding solutions allow for maximum control, while automated systems deliver high accuracy at faster speeds.

- Comprehensive Support: Success goes beyond machinery. Our team provides on-site training, equipment calibration, and ongoing maintenance to ensure you reach optimal performance every time.

- A Broad Range of Equipment: From welding machines to materials like pipe plugs and exchanger mills, SEC Automation supplies everything needed to meet aerospace welding challenges head-on.

How Does Autonomous Welding Help Aerospace Quality Standards?

The use of autonomous welding leads to significant improvements in aerospace quality standards in several areas, including:

- Material Strength: Welded components often outlast traditionally joined parts due to tighter tolerances and consistent heat application.

- Dimensional Accuracy: Automation eliminates gaps, undercuts, and other physical inconsistencies.

- Regulatory Compliance: Meeting the stringent safety and performance standards of the aviation industry becomes easier with foolproof processes.

Building the Future of Aerospace Welding

With aerospace demands only growing, the role of autonomous welding will continue to expand. At SEC Automation, we remain at the forefront of this evolution, helping our clients achieve the highest levels of safety, durability, and efficiency. By delivering innovative welding technologies, we aim to help you exceed industry standards and build trust with your customers.

To learn more about how SEC Automation can provide the best welding solutions for your aerospace projects, contact us today. Together, we can set new benchmarks for quality.