Managing pipe fabrication comes with enough challenges, like tight deadlines, strict quality requirements, and ongoing pressure to keep costs in check. Over the years, more fabricators have turned to pipe spool welding machines to meet these demands with greater efficiency and accuracy. Instead of offering another sales pitch, let’s break down what these machines actually do for real projects and how they can make a tangible difference.

Understanding Pipe Spool Welding Machines

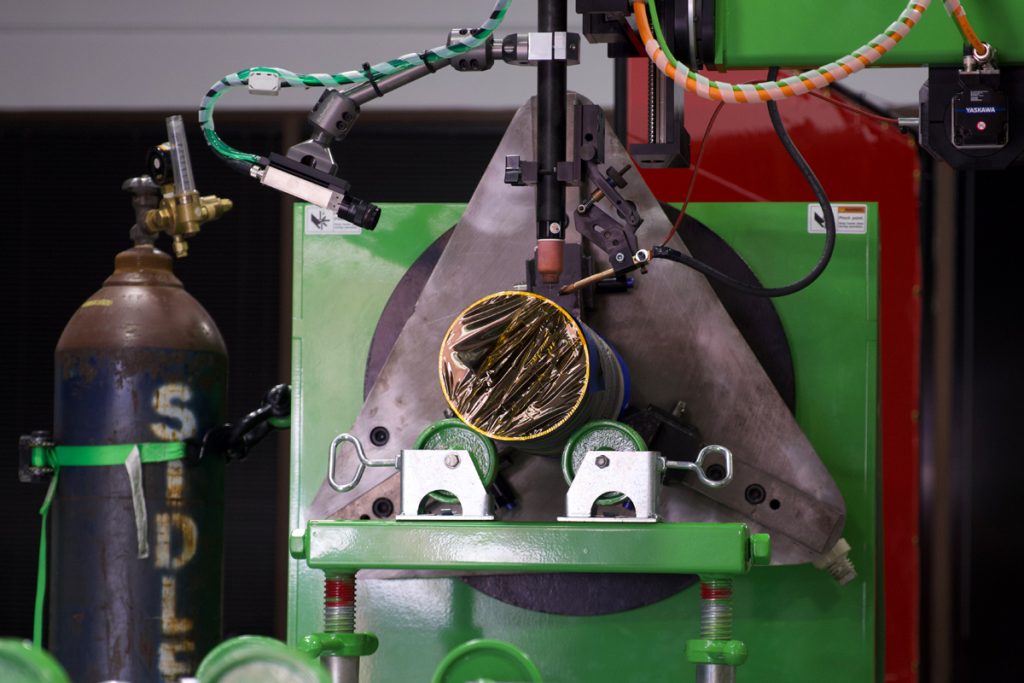

At their core, pipe spool welding machines automate what was once a very hands-on, repetitive process. They’re engineered to weld pre-fabricated sections of piping, called spools, that get joined together on site. With features like programmable controls, hotwire TIG technology, and built-in monitoring, these machines are built to handle the technical details that manual welders juggle every day.

Key Advantages

- Programmable, consistent operation

- Precision in repetitive tasks

- Reduced need for manual adjustments

Where Do the Biggest Time Savings Happen?

The advantage of using pipe spool welding machines often comes down to efficiency across the workflow.

Accelerated Welding Cycles

With machines set up to handle multiple weld passes and rapid position changes, wait time drops. Welding that took hours can now take minutes, and mistakes due to human fatigue are less common.

Faster Job Setups

Rather than spending time dialing in every parameter between joints, operators can load preset programs. This is especially valuable for fabricators running batches of similar pipe spools.

Overlapping Tasks

Some welding systems support simultaneous staging and welding. In a busy shop, this means less idle equipment and more work done over each shift.

Fewer Redos

Machines are programmed to hit the same specs every time, making defects far less likely. Teams spend less time reworking poor welds and more time pushing projects forward.

Labor and Cost Considerations

Adding automation isn’t just about speed. It’s also about how you use your team’s skills.

Fewer Workers Needed

One operator can safely oversee more machines, so experienced welders can focus on high-skill tasks or quality control while less experienced staff run basic programming.

Less Material Waste

Consistent welding means fewer errors and less scrap. This adds up over large projects, reducing both costs and environmental impact.

Long-Term Investment

There’s an up-front cost for automated welding machines, but the benefits accumulate quickly: labor savings, reduced rework, and improved material use all directly affect project budgets.

Weld Quality and Consistency

In pipeline work, a single bad weld can have major consequences. Automation offers a level of consistency that’s tough to match with manual labor alone.

- Precision: Weld settings like speed, torch angle, and heat input are consistent from joint to joint.

- Repeatability: Once you dial in optimal settings, every spool gets the same quality treatment.

- Adaptability: These machines are built to handle a range of pipe diameters and wall thicknesses, giving fabricators flexibility.

When Automated Welding Makes Sense

Automated pipe spool welding machines are particularly useful for shops with repetitive, high-volume work or those where skilled welders are in short supply. With built-in monitoring and real-time data, quality slips are spotted early, reducing the risk of expensive fixes later.

Features to Consider

- Easy-to-use programmable interfaces

- Support for TIG and hotwire TIG processes

- Integrated quality monitoring to track weld integrity

Pipe Spool Welding Machines: A Practical Solution

Pipe fabrication keeps getting more complex, but the goals remain the same: deliver safe, precise, and cost-effective results. Pipe spool welding machines aren’t a cure-all, but they’ve proven to be a practical solution for many modern fabrication challenges, especially when you want steady throughput and less dependence on a shrinking skilled labor pool.

If your operation is ready to streamline welding tasks, minimize errors, and put time back on the clock, it might be time to take a closer look at pipe spool welding machines. Want more technical info or to see options in person? Reach out to SEC Automation for an in-depth discussion about your shop’s needs and whether automation could make your next project run smoother.