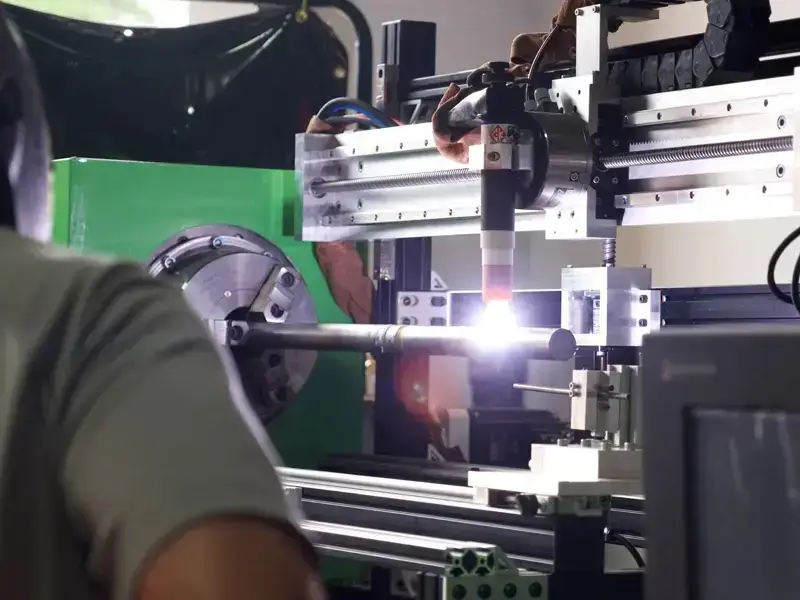

Let’s talk about something that’s essential for any company working with industrial pipelines: getting the job done right and getting it done fast. In a competitive industry, every minute and every weld counts. At SEC Automation, we’ve seen how automated welding takes welding from a manual, time-consuming process to a streamlined, efficient operation. Here are five key ways automated welding can seriously boost your productivity.

1. Speed and Consistency That Never Quit

When it comes to pipeline fabrication, manual welding can be slow. Welders need breaks, and fatigue can lead to inconsistencies. Automated welding systems, on the other hand, can run continuously. They deliver a high-quality, uniform weld every single time, at speeds that manual welding just can’t match. This consistency means you get flawless results faster.

2. A Higher Level of Quality You Can Trust

The integrity of a pipeline is everything. A weak weld can cause major problems down the road. Automated systems use pre-programmed settings and advanced controls to perform welds with incredible precision. This eliminates the human error that can lead to common issues like porosity or cracking. The result? A stronger, more reliable pipeline and less time spent on costly re-work and inspections. Our AutonoWeld product line is built on this principle: quality you can count on.

3. A Safer Way to Work

Welding is a tough job, and it comes with real risks. Welders are exposed to fumes, intense heat, and cutting hazards. By bringing automated welding into your workshop, you’re moving your team away from these dangers. One operator can safely manage multiple robotic systems from a distance, allowing them to focus on quality control instead of risking their health. It’s a simple change that makes your workplace safer and helps you meet those all-important safety regulations.

4. Less Waste, More Savings

Errors in manual welding often mean scrapped materials and wasted time. Automated welding systems are so precise that they drastically reduce these issues. They use filler metal and other consumables with maximum efficiency, and the risk of needing to throw out a finished piece is nearly non-existent. This not only saves on materials but also drives down overall project costs, giving you a solid return on your initial investment.

5. Beating the Skilled Labor Shortage

Finding skilled welders is getting tougher all the time. Automated welding helps solve this problem by taking on the repetitive, more basic welding tasks. This frees up your most experienced welders to focus on the complex, high-value jobs that truly require their expertise. It’s about making the most of your team and ensuring you can keep up with production demands, even when the labor market is tight.

Ready to Experience the Power of Automated Welding?

If you want to boost your productivity, improve weld quality, and make your workplace safer, it’s time to consider automated welding. At SEC Automation, we don’t just sell machines; we provide purpose-built solutions designed for real-world industrial demands. Our team is ready to help you simplify your workflow and get real results.

Contact SEC Automation today to see how our AutonoWeld systems can cut downtime, increase throughput, and solve your skilled labor challenges.