Industry Insights

Updates & Ideas From Our Team of Experts

Recent Articles

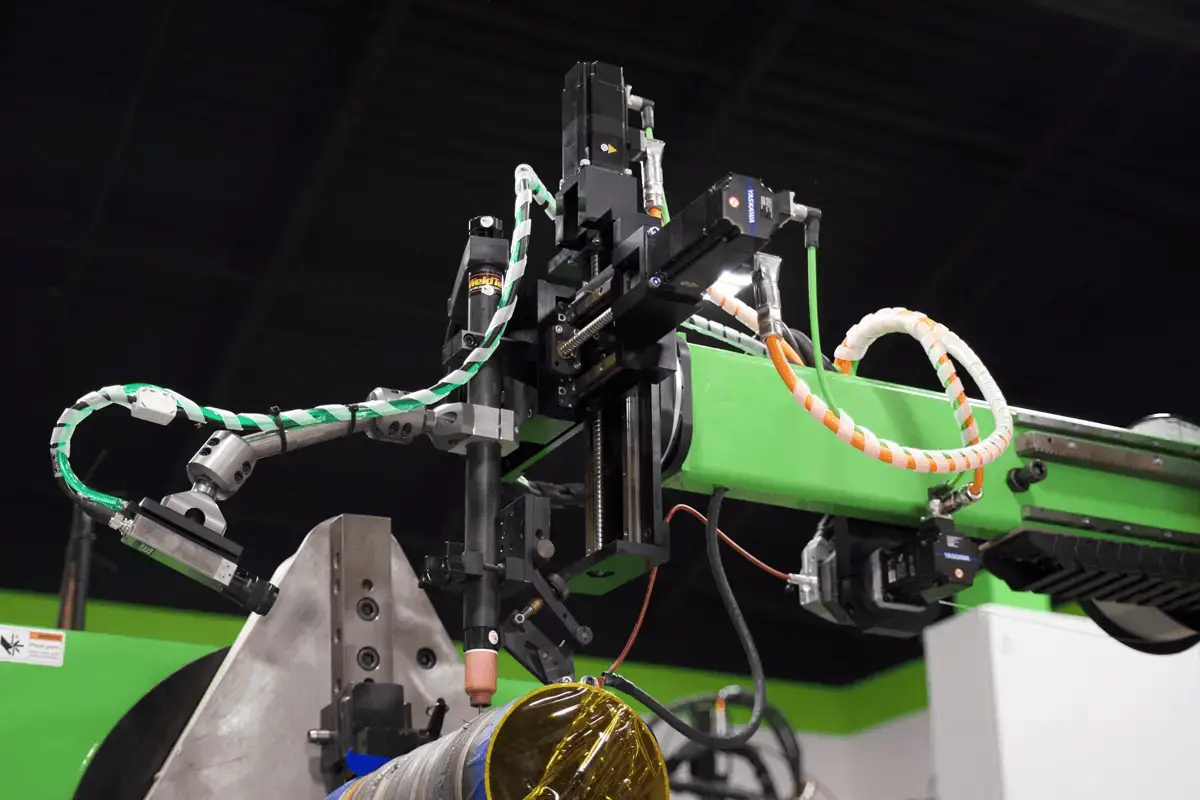

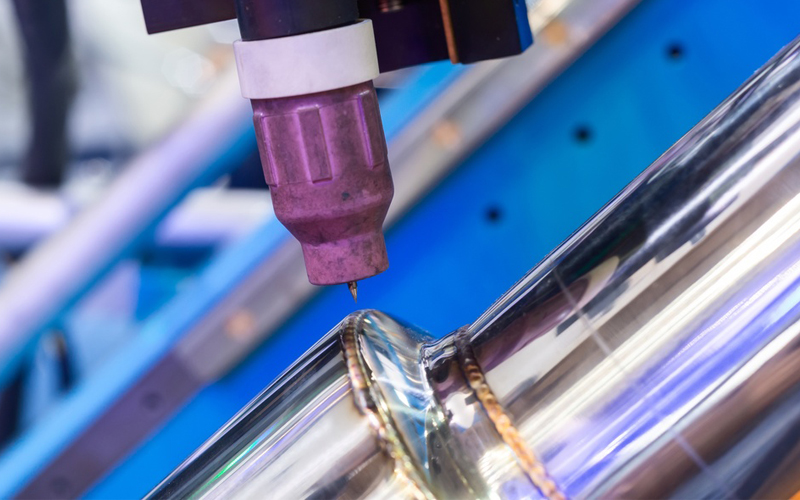

Orbital Welders Explained: Benefits, Use-Cases and What to Consider Before Purchase

High-specification fabrication demands precision that is increasingly difficult to achieve with manual processes alone. Whether you are welding stainless steel tubing for semiconductor plants or heavy-wall pipes for the energy sector, the margin for error is shrinking. Fabrication shop owners...

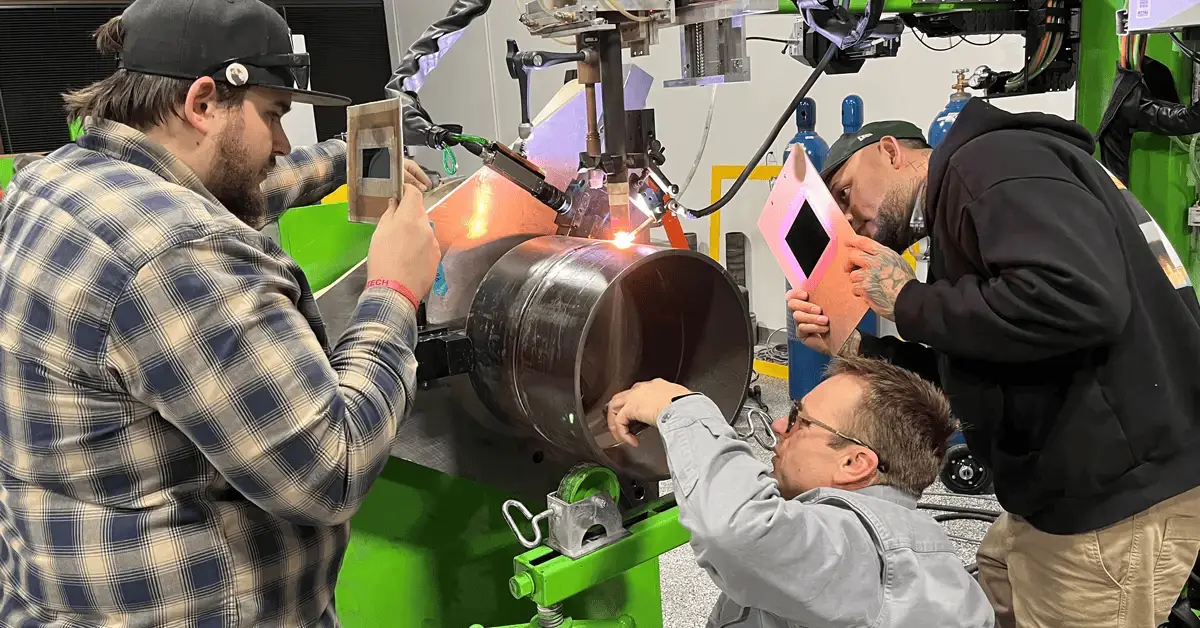

How Automated Welding Bridges the Skilled Labor Gap in Modern Fabrication Shops

Fabrication shops across the country are facing the same difficult reality. You have the contracts, you have the raw materials, and you have the deadlines. The one thing you are missing is enough skilled hands to do the work. The...

What 2025 Revealed About Automated Welding

Future-proof your facility with automated welding tech that boosts efficiency, consistency, and long-term productivity for modern manufacturers.

How to Future-Proof Your Facility With the Latest in Automated Welding Technology

Future-proof your facility with automated welding tech that boosts efficiency, consistency, and long-term productivity for modern manufacturers.

Top 5 Maintenance Considerations for Automated Welding Equipment in 2026

Proper maintenance is essential to keep automated welding systems running at peak performance. From calibration and consumables to software updates and data monitoring, discover the top five ways fabrication shops can reduce downtime, improve weld quality and protect their investment...

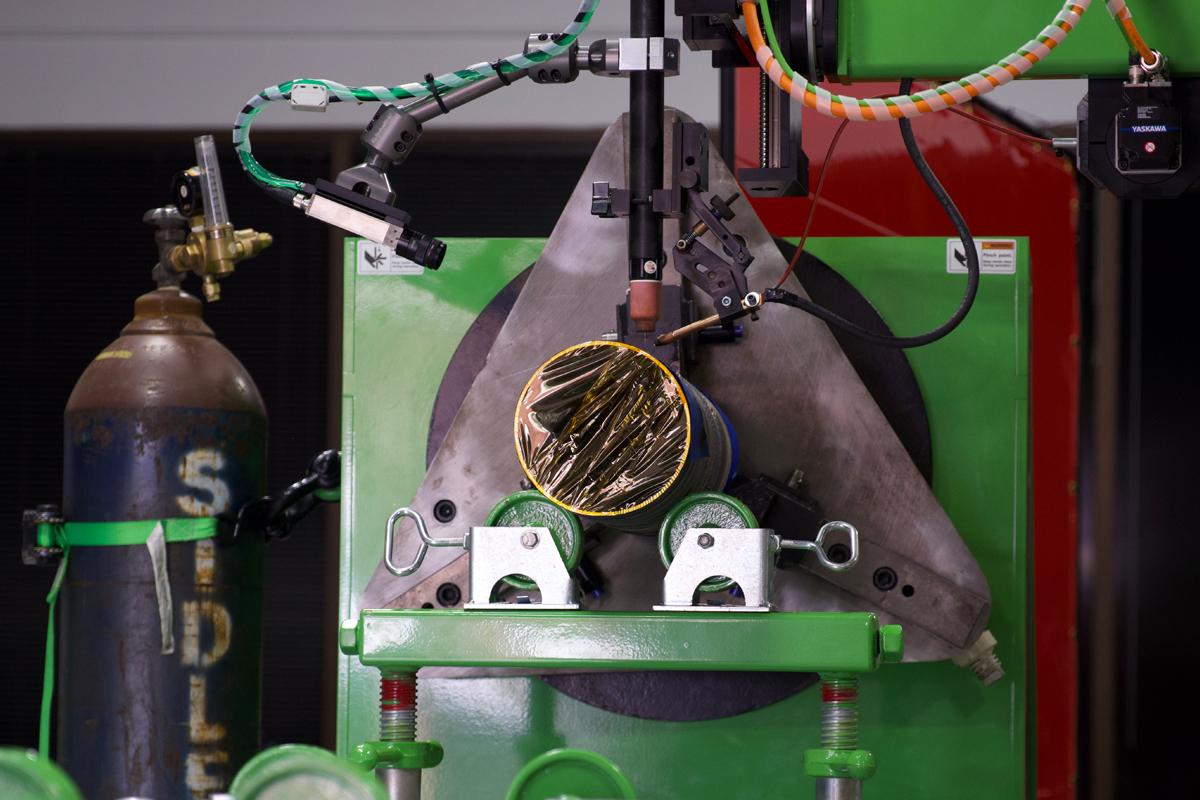

Automated Welding Systems: How to Choose the Right Setup for Your Pipe Fabrication Line

Automated welding is transforming pipe fabrication by boosting speed, precision and consistency. Learn how to choose the right welding system for your production line and what real-world factors matter most before investing.

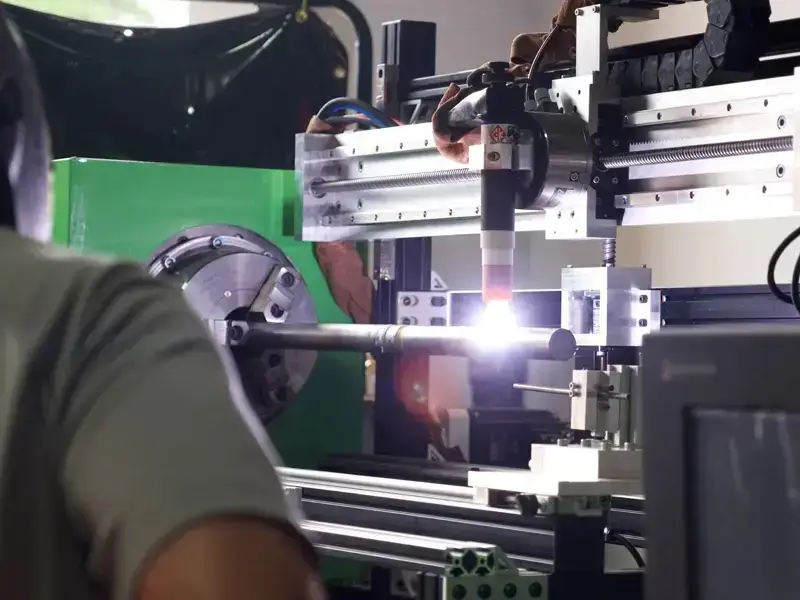

How an Automated Pipe Welding Machine Boosts Shop Throughput

Let’s talk through your current process and see how a system like the AutonoWeld M3 automated pipe welding machine can help you boost both quality and throughput.

Why Aerospace-Grade Precision Welding Tools Are Essential for Industry Compliance

Our work with AutonoWeld automated welding solutions is focused on implementing the principles of precision and repeatability in aerospace-grade precision welding tools.

What FABTECH 2025 Revealed About the Future of Automated Welding

Explore how FABTECH 2025 showcased automation as the future of welding, with cobots, AI, and data-driven systems transforming fabrication.

5 Ways Automated Welding Boosts Productivity in Industrial Pipelines

Discover how SEC Automation’s automated welding solutions boost pipeline productivity with faster, safer, and more precise welds.

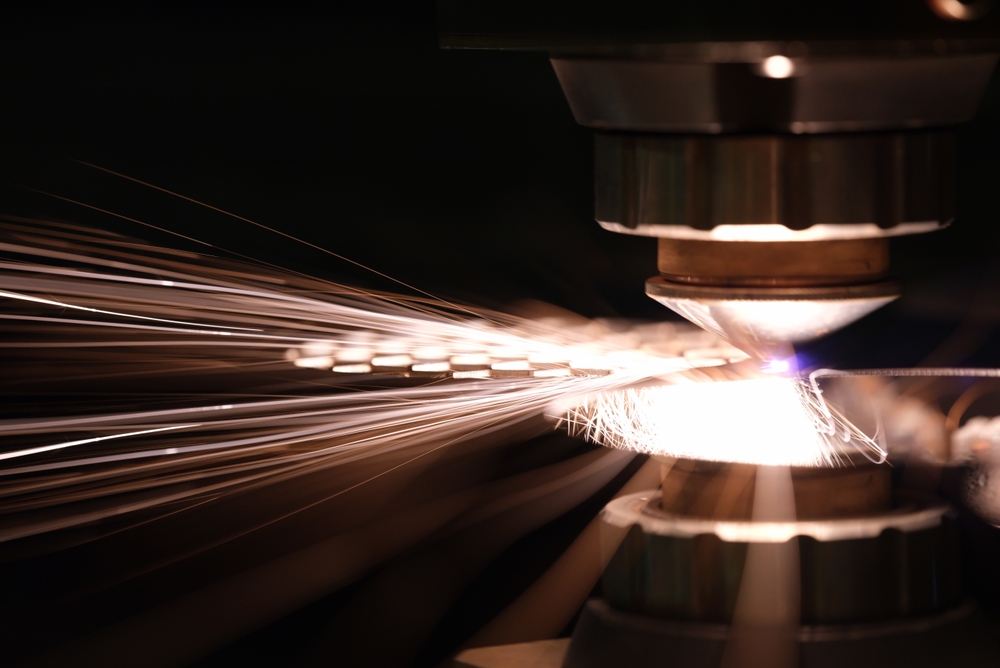

How Orbital Welding Automation Prioritizes Safety

Discover how orbital welding automation prioritizes operator safety through consistent quality, fabricator protection, and intelligent system design.

Automating Calibration in Orbital Welding Systems

Learn how automating calibration in orbital welding systems improves consistency, quality, and efficiency. Explore key steps and integration tips.

How Pipe Spool Welding Machines Save Time and Labor

Reach out to SEC Automation to discuss your shop’s needs and find out how our automated pipe spool welding machines could make your next project run smoother.

All About Pipe Bevelers: How & Why They’re Used

Learn all about how and why pipe bevelers are used in welding projects, from manual tools to CNC machines built for high-precision industrial applications.

Advanced Defect Detection in Orbital Welding

Learn how to spot welding defects, from porosity to arc instability, using real-time data from orbital welders. Smarter welds start with better insights!

The Role of Autonomous Welding in Enhancing Aerospace Quality Standards

With aerospace demands only growing, the role of autonomous welding will continue to expand. At SEC Automation, we remain at the forefront of this evolution.

Precision & Productivity: Unlocking the Power of AMI

Learn how to boost your precision and productivity using AMI orbital welding systems with actionable tips, settings, and real-world techniques.

Troubleshooting Weld Root Penetration Issues

Learn eight practical solutions for troubleshooting weld root penetration issues and improving fusion, consistency, and overall weld quality.

Post-Weld Heat Treatment for Weld Integrity

Learn why post-weld heat treatment for weld integrity is essential and how welders can avoid mistakes to ensure strong, code-compliant results.

Understanding the True Costs of Welding Defects

Welding defects impact operational costs, worker safety, and workplace productivity. Learn strategies for prevention and understand the price of welding flaws.

Recent Posts

- Orbital Welders Explained: Benefits, Use-Cases and What to Consider Before Purchase

- How Automated Welding Bridges the Skilled Labor Gap in Modern Fabrication Shops

- SEC Automation Announces Full AutonoWeld Orbital Product Line Now Available for Industrial and High-Purity Fabrication

- What 2025 Revealed About Automated Welding

- How to Future-Proof Your Facility With the Latest in Automated Welding Technology