Precision and reliability are the hallmarks of orbital welding equipment, making it essential for professionals in aerospace, pharmaceuticals, and food processing. These systems deliver consistent and clean welds, and their performance depends heavily on regular maintenance.

Neglecting upkeep can lead to reduced efficiency, operational delays, and expensive repairs. This guide walks you through practical steps to troubleshoot orbital welding equipment and maximize its effectiveness.

Common Mistakes Leading to Equipment Wear

Before exploring maintenance steps, we’ll share some common operator behaviors that negatively impact orbital welders. Avoiding these foundational errors lays the groundwork for consistent performance and reduces the risk of system failures down the line.

Improper Cleaning

Residual contaminants, including grease and oxidation byproducts, often build up in tungsten electrodes and clamping tools. Residue can negatively affect weld quality and damage sensitive parts in the long run.

Skipping Regular Calibration

Skipping or delaying calibration can disrupt weld consistency, leading to imperfections during projects. Regular adjustments help your equipment deliver the weld parameters you need.

Poor Storage Practices

Environmental factors, such as humidity, dust, or extreme temperatures, can prematurely wear down electronic components of the equipment, including cables and power sources. Never overlook safe storage conditions when the machine is not in use.

Step-By-Step Guide to Maintaining Orbital Welding Equipment

Keeping your orbital welding equipment in top condition requires a combination of daily care and long-term maintenance strategies. Here’s how to do it right:

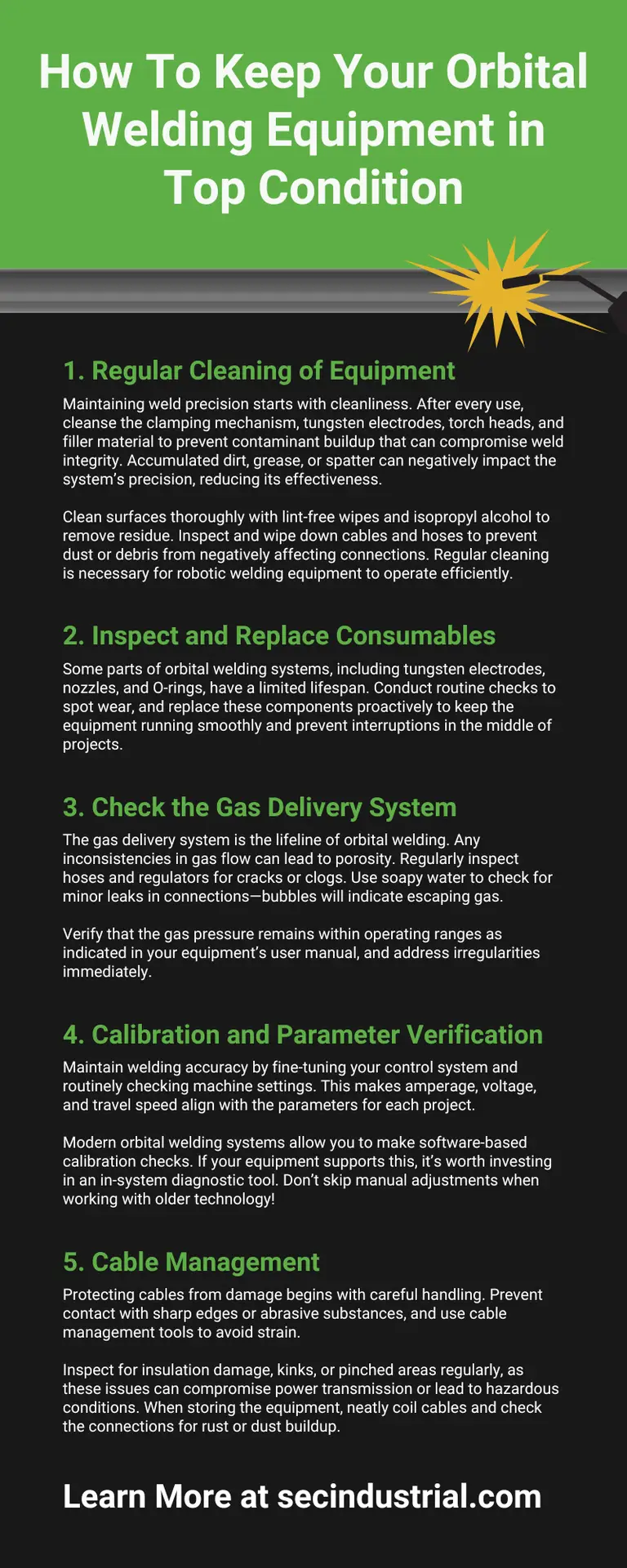

1. Regular Cleaning of Equipment

Maintaining weld precision starts with cleanliness. After every use, cleanse the clamping mechanism, tungsten electrodes, torch heads, and filler material to prevent contaminant buildup that can compromise weld integrity. Accumulated dirt, grease, or spatter can negatively impact the system’s precision, reducing its effectiveness.

Clean surfaces thoroughly with lint-free wipes and isopropyl alcohol to remove residue. Inspect and wipe down cables and hoses to prevent dust or debris from negatively affecting connections. Regular cleaning is necessary for robotic welding equipment to operate efficiently.

2. Inspect and Replace Consumables

Some parts of orbital welding systems, including tungsten electrodes, nozzles, and O-rings, have a limited lifespan. Conduct routine checks to spot wear, and replace these components proactively to keep the equipment running smoothly and prevent interruptions in the middle of projects. Here are a few tips for doing so:

Tungsten Electrodes

Grind and reshape electrodes when they show wear or contamination. Use a dedicated grinder for tungsten to perfect their geometry.

O-Rings and Seal

Always check for cracks or elasticity loss in seals. These small components prevent gas leaks and maintain a stable environment for the weld.

Torch Tips and Cups

Replace torch tips if you notice excessive spatter buildup that cleaning cannot rectify.

3. Check the Gas Delivery System

The gas delivery system is the lifeline of orbital welding. Any inconsistencies in gas flow can lead to porosity. Regularly inspect hoses and regulators for cracks or clogs. Use soapy water to check for minor leaks in connections—bubbles will indicate escaping gas.

Verify that the gas pressure remains within operating ranges as indicated in your equipment’s user manual, and address irregularities immediately.

4. Calibration and Parameter Verification

Maintain welding accuracy by fine-tuning your control system and routinely checking machine settings. This makes amperage, voltage, and travel speed align with the parameters for each project.

Modern orbital welding systems allow you to make software-based calibration checks. If your equipment supports this, it’s worth investing in an in-system diagnostic tool. Don’t skip manual adjustments when working with older technology!

5. Cable Management

Protecting cables from damage begins with careful handling. Prevent contact with sharp edges or abrasive substances, and use cable management tools to avoid strain.

Inspect for insulation damage, kinks, or pinched areas regularly, as these issues can compromise power transmission or lead to hazardous conditions. When storing the equipment, neatly coil cables and check the connections for rust or dust buildup.

6. Maintain Cooling Systems

Orbital welding systems often require water or air cooling to regulate the temperature of their components. Double-check the coolant levels (if applicable), and clean heat exchange surfaces regularly. Blocked or inefficient cooling systems can lead to overheating and damage to internal parts. Use only the coolant type or grade specified by the manufacturer.

For water cooling systems, flush the cooling lines periodically to remove mineral deposits that could impede flow. Don’t underestimate the danger of heat buildup because it can severely reduce the lifespan of electronic components.

7. Implement Preventative Maintenance Schedules

Partner with a professional or follow the manufacturer’s recommendations to establish a preventative maintenance schedule. Outsourcing an expert inspection once or twice a year can help you identify and address barely noticeable issues before they worsen.

At SEC Automation, we specialize in supporting customers with orbital welding system maintenance schedules. Our expertise contributes to the functionality of your equipment!

8. Store in Optimal Conditions

Preserve your orbital welding equipment by storing it in a clean, dry environment with stable temperatures. Use dust covers for equipment that you won’t use for extended periods, and avoid stacking components in a way that could lead to warping, bending, or accidental damage.

Humidity is particularly harmful, as moisture can cause rust on metallic parts or cause electrical components to short circuit. Make sure the storage environment is not humid.

Troubleshooting Common Problems

Even with diligent maintenance, occasional problems may arise. When in doubt, refer to the manufacturer’s manual or consult a professional technician. Here are some troubleshooting tips for addressing common concerns:

- For uneven weld beads, check the alignment of the clamping mechanism to facilitate gas flow.

- For power issues, inspect the power cord for kinks or breaks and verify the integrity of the connection.

- Arching or excessive spatter is due to worn tungsten or insufficient cleaning. Replace the part and wipe all components thoroughly.

Why Maintenance Is Worth the Time

Maintaining orbital welding equipment may seem demanding, but it pays dividends. Functional equipment reduces downtime, extends machine life, and produces superior welds.

Understanding how to keep your orbital welding equipment in top condition is key to reaping these benefits. Regular maintenance reduces the risk of malfunctions, enhances workplace safety, and enables your machinery to perform at its best. With consistent upkeep, your equipment will meet the demands of your industry.