A struggling economy often shines a spotlight on customer relations and product quality. That’s because clients become even more careful about where they spend their money when budgets are tight. As a result, you may find your industry more competitive than it normally is.

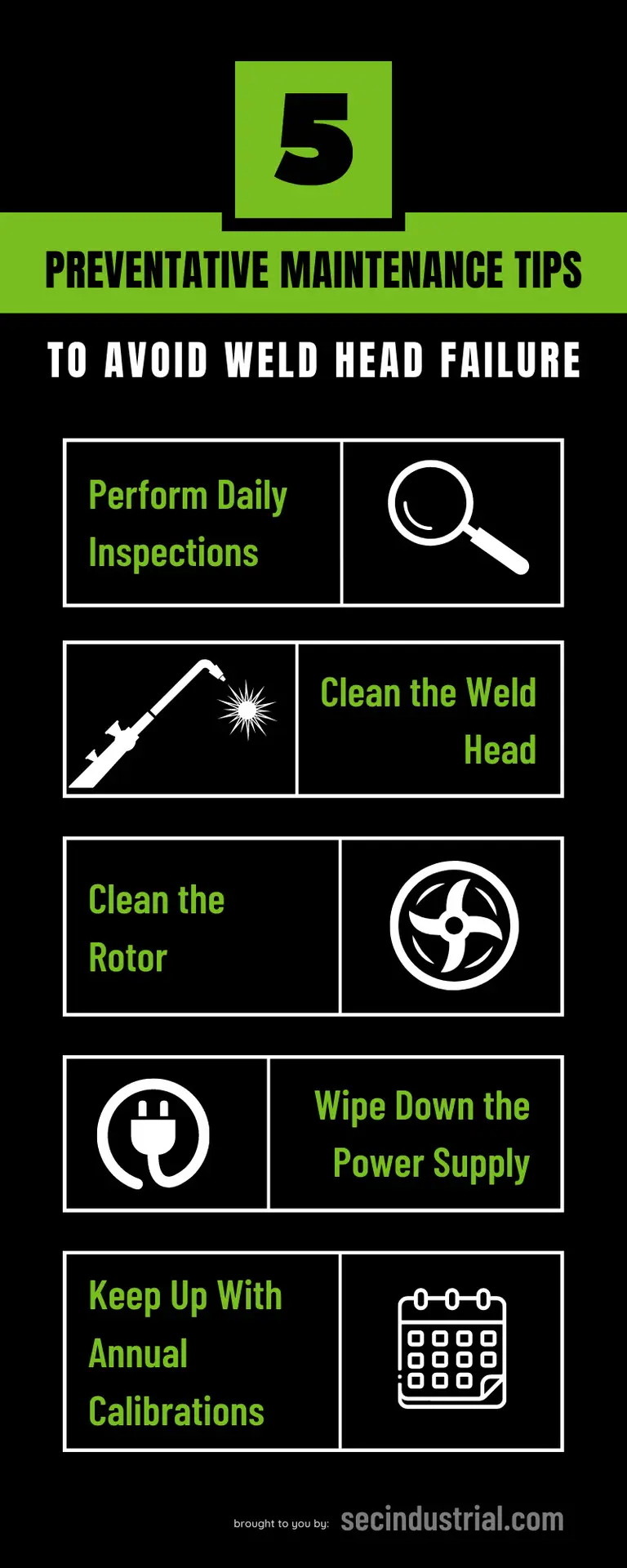

Small hiccups in production can become larger delays that frustrate customers and cost you business. During times like these, it’s more important than ever not to lose track of the details. In orbital welding, that means setting aside time for routine maintenance so your equipment stays in top working condition. Below is information on weld head failure, along with five preventative maintenance tips to avoid it.

What Is Weld Head Failure?

The weld head is the device orbital welders use to weld pipes and other cylindrical pieces of metal. Weld head failure is just a term for when the weld head isn’t working correctly. Since a weld head is a complex piece of equipment, many reasons could cause you to experience weld head failure. Some examples of weld head failure are bad starts, continuous spinning, and overheated clamps.

Bad Start

If you start the welding cycle and end up with splatters and odd noises, you have a bad start. A bad start could happen for many reasons. You might have a poor-quality piece of tungsten, or it might not be in the feed correctly. You could also have an incomplete pre-purge, which means other atmospheric gases are clogging up the shielding gas.

Continuous Spinning

If the sensors in your weld head are not working properly, you may end up in a situation where the rotor spins continuously. This may also be a sign of broken wires somewhere in the assembly. Unfortunately, this kind of error is not something you should try to fix in-house unless you have a specialized weld head technician.

Overheated Clamps

Overheated clamps can happen when your weld head isn’t getting enough coolant. Thankfully, you may be able to solve it quickly by increasing the coolant flow. Alternatively, you may have a blockage to clear out first. For this, all you need to do is backflush the coolant lines on the power supply.

Why You Should Try To Avoid Weld Head Failure

When your equipment isn’t working correctly, it can cause a chain reaction of other problems. For example, if your welding equipment fails at the start of the workday, you might have to spend most of the day troubleshooting the problem. If you’re already on a tight deadline, your clients could get worried about your ability to fulfill your contracts. And even if you fulfill the order, they might not decide to come back next time they have a similar project.

Furthermore, if the maintenance is something too complicated to do in-house, you may even have to ship your equipment to a third party for repairs. And we all know how slow the current shipping networks are, so wait times for deliveries are longer than usual. Waiting for your equipment to return can put projects on hold even longer, further risking your relationships with clients. Avoiding these situations is the best way to keep clients happy and your business competitive.

What You Can Do To Prevent Weld Head Failure

Thankfully, you can take steps to prevent many of these costly repairs. Preventative maintenance on your equipment is the first line of defense against malfunctions because it gets rid of problems before they happen. It also gives you a chance to spot wear and tear on your equipment. Below are five steps you can take to keep bigger problems from developing.

1. Perform Daily Inspections

The first step of preventative maintenance to avoid weld head failure is performing daily inspections. Take five minutes at the beginning and end of the workday to give your weld heads a visual inspection so you can see if there are any problems. You may find your equipment is in top condition at the start of the day but not at the end. Knowing about the problem before the next day begins can help you avoid delays. Some things to look for in and around weld heads are the following:

- Discoloration, especially bluing of metal or darkening of glass lenses

- Leaks in coolants, lubricants, or shielding gases

- Fouling from spatter, especially if it impedes weld head movement

- Wear on wire feeds, wire rollers, or scratching near wire tips

2. Clean the Weld Head

This piece of advice is pretty straightforward. You should clean the weld head to remove dirt, debris, and metal spatters that could hurt your equipment over time. Often, debris becomes a trap for bacteria, which can lead to corrosion and wire shorts. To clean the weld head, make sure the power supply is off, and wipe the inside of the head with a cloth sprayed with denatured alcohol.

3. Clean the Rotor

The rotor is another part of the weld head you should pay special attention to. As we mentioned earlier, you can end up with a spinning rotor if the sensors aren’t working correctly. Use the same technique as above to clean the rotor, making sure to avoid spraying the weld head directly with the denatured alcohol.

4. Wipe Down the Power Supply

Since so much about orbital welding depends on the power supply, make sure to give it a quick wipe-down at the end of every day. Dust and bacteria can build up over time, leading to wire shorts and corrosion. Plus, if your power supply were to overheat, debris could also provide the combustible material for a fire.

5. Keep Up With Annual Calibrations

Every year, you should send your welding equipment to a professional for calibration. This will ensure your equipment stays in working condition as long as possible. It can also save you from costly mistakes and project delays. However, since sending your equipment in takes time, be sure to plan this maintenance for the slow season.

Professional Orbital Welding Equipment

Another step you can take to prevent unexpected repairs is to start using professional-grade welding equipment. You can find automatic pipe spool welding machines at SEC Automation. We’re proud to offer the M3 welding system, which is perfect for fabricating pipe spools. In fact, you can get successful results with our equipment even if you only have minimal welding experience yourself. For more information, reach out to our experts at SEC Automation!