Think about the tools that people use during a regular repair job. Having a diverse kit with tools for every scenario is important. Welding jobs put you in difficult situations where different tools are necessary to make it easier for you to work. Whether you are working with a rusted metal panel or a standard set of electrical wires, getting into the spot you need to repair is not always the easiest task. Wrenches and pliers are standard tools in your kit that help clear the way. The last thing you want is to be unprepared for a sealed entry. Knowing the proper way to use torque wrenches for welding is an important skill to have under your toolbelt for future jobs.

The Point of Your Torque Wrench

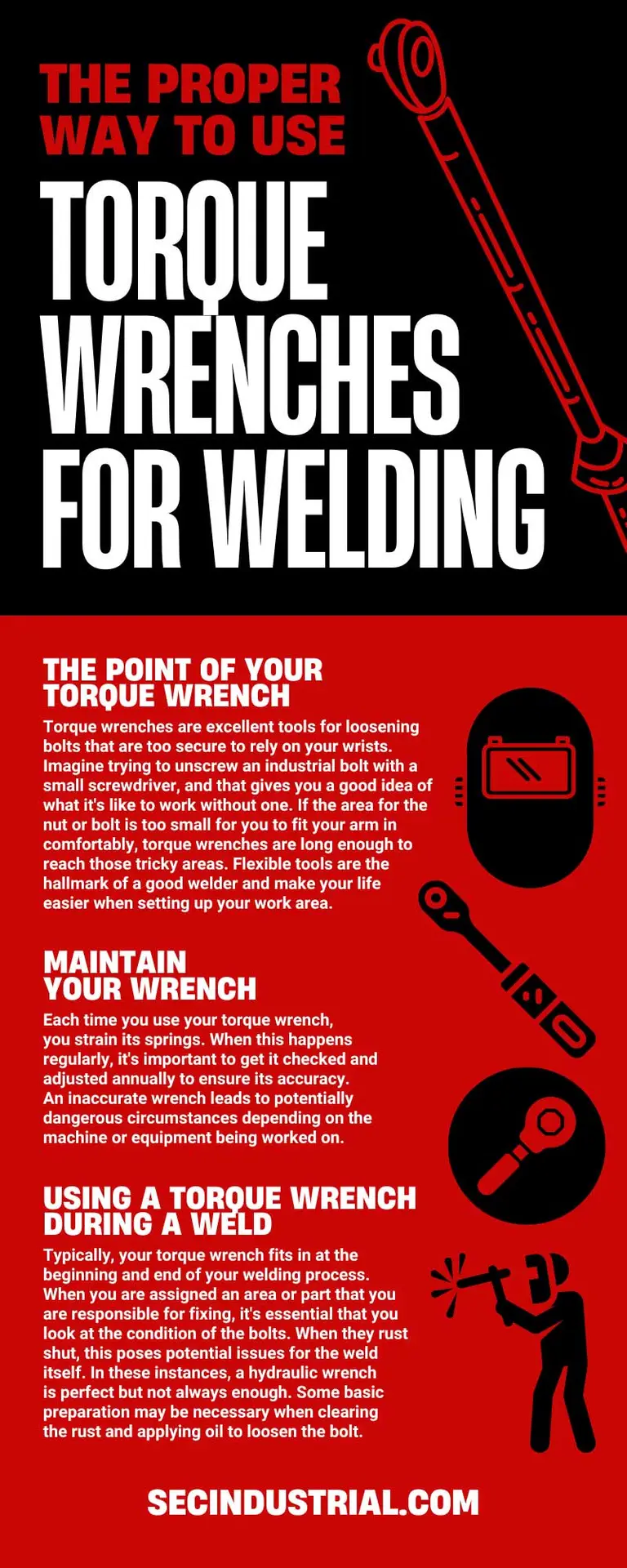

Torque wrenches are excellent tools for loosening bolts that are too secure to rely on your wrists. Imagine trying to unscrew an industrial bolt with a small screwdriver, and that gives you a good idea of what it’s like to work without one. If the area for the nut or bolt is too small for you to fit your arm in comfortably, torque wrenches are long enough to reach those tricky areas. Flexible tools are the hallmark of a good welder and make your life easier when setting up your work area.

These wrenches also help to put less strain on the body. By leveraging your weight with the tool, bolts become much easier to loosen. Without wrenches, you would either struggle significantly more with tight bolts or be unable to loosen them at all. This benefit is noticed years down the line and saves you pain in the wrists. No one wants to suffer for doing a good job, and a torque wrench ensures your preparations are easier moving forward.

Kinds of Torque Wrenches

There are a variety of torque wrenches from which to choose. While they perform a similar roles in the workplace, the differences between them make them ideal for specialized situations. Before knowing the proper way to use your wrench, it’s important to understand the options you can choose from.

- Electronic: These wrenches are perfect combinations of new technologies and classic innovations. Electronic torque wrenches come with important information, such as the bolt’s total torque power.

- Beam: Beam torque wrenches are more popular within the automotive industry. Very few garages find themselves without this wrench somewhere in a toolbox. These are classic tools with precise measurements that allow mechanics to fasten bolts on the wheels of a car.

- Click: When most people think of a torque wrench, they typically think about the clicking kind. These wrenches have a shorter handle. You can continue work without detaching the wrench. The number of clicks correlates to the torque you apply each time you use it.

- Slip: When the job requires a small amount of torque to undo the bolt, slip torque wrenches are perfect. Due to their design, there is no need to worry about overtightening the bolt you are working on.

- Deflecting Beam: Deflecting beam wrenches are longer and provide visual and auditory information. When torque is applied through the wrench, it actively measures how much is applied.

- Hydraulic: For those dealing with heavy industrial tools and machines that require securely locking bolts, a high-torque hydraulic wrench is a solution. This mainstay device is a great asset to welders who want to get in and out of heavy equipment quickly without putting much effort into the process.

Maintain Your Wrench

As a welder, ensuring your tools last as long as possible is important. With how much force is being applied to them regularly, it’s a good idea to keep your tools in good condition. Each time you use your torque wrench, you strain its springs. When this happens regularly, it’s important to get it checked and adjusted annually to ensure its accuracy. An inaccurate wrench leads to potentially dangerous circumstances depending on the machine or equipment being worked on. Having one that can accurately measure the force being applied to it allows you to keep things precise with certainty.

Using a Torque Wrench During a Weld

Typically, your torque wrench fits in at the beginning and end of your welding process. When you are assigned an area or part that you are responsible for fixing, it’s essential that you look at the condition of the bolts. When they rust shut, this poses potential issues for the weld itself. In these instances, a hydraulic wrench is perfect but not always enough. Some basic preparation may be necessary when clearing the rust and applying oil to loosen the bolt. During this phase, there is no need to have your welding tools active. It’s best to keep them away from your other tools until you are finished with the site.

On the other hand, you need a way to reseal your work area after finishing it. After neatly putting away your welding tools, it’s time to collect any nuts or bolts you loosened and fasten them back on. It’s a good idea to keep them in an easy-to-remember location but preferably not on you. Unless they are in a secure and enclosed spot, there’s a chance they can slip out during your work. This goes for your tools as well. If they are not currently being used, it’s worth putting them away and isolating them until you finish your job.

Whether someone is working on a bridge repair, an elevator, or a dishwasher, there are different instances where torque can find its use and make your life easier. While it isn’t the first thing on people’s minds when they think about welding, it is still a necessary tool that makes the overall process easier for you. Similar to why you should wear your welding mask at all times during a job, these are tools that help prevent injury in the future. No one wants to feel aches or pains in their wrists due to forgoing a torque wrench to save a few extra bucks. By understanding the proper way to use torque wrenches for welding and the importance of the tool, they can take advantage of it sooner rather than later.