In any manufacturing field where reliability is non-negotiable, the quality of a weld is fundamental. It’s an area where “good enough” simply doesn’t cut it. This is the principle behind aerospace-grade precision welding tools. Developed to meet the incredibly strict safety and performance demands of aviation and space exploration, these tools embody a higher standard of engineering. Their value, however, isn’t limited to the aerospace sector; the principles they follow are becoming essential across many modern industries.

A Weld’s Critical Role in Product Integrity

A weld is more than just a joint; it’s a point of potential stress and failure. For a complex piece of machinery, a vehicle, or even medical equipment, the integrity of every single weld contributes to the safety and longevity of the final product. When a part fails, the investigation often leads back to a microscopic flaw in a weld. Using aerospace-grade precision welding tools is about mitigating that risk from the very beginning. It’s a methodical approach to ensuring that every connection is as strong and reliable as the materials it joins.

What Defines “Aerospace-Grade” Welding?

The term “aerospace-grade” isn’t about marketing; it signifies a specific set of capabilities designed for absolute consistency and traceability. These tools are built to control every variable in the welding process, ensuring the result is predictable and repeatable. Key characteristics include:

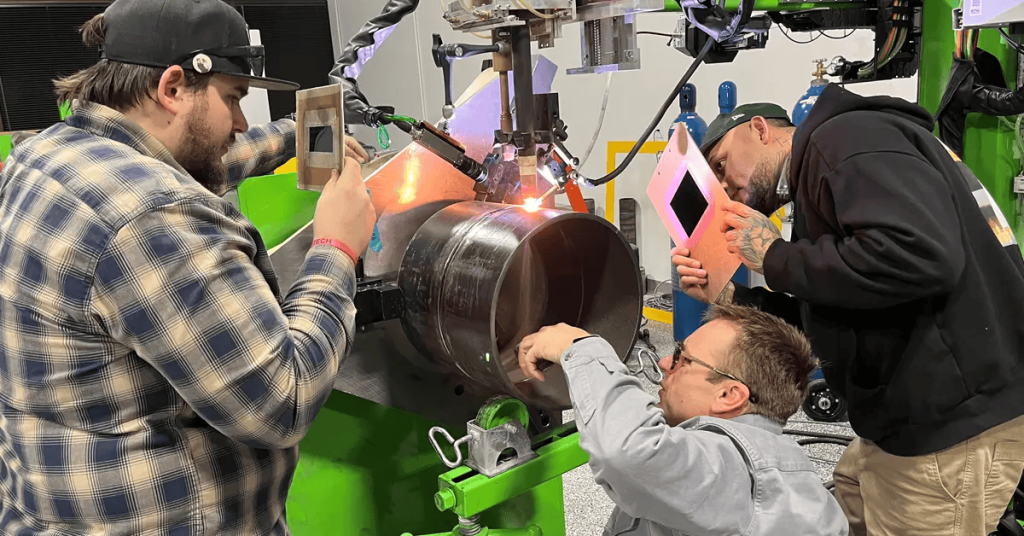

- Process Control: These systems provide precise, computer-controlled regulation of parameters like heat, speed, and filler material deposition. This removes the variables inherent in manual welding, leading to a much more consistent result.

- Automation for Repeatability: Automation is key to achieving identical welds every time. A robotic arm can replicate a perfect weld path thousands of times without fatigue or minute variations, which is crucial for large-scale production and regulatory compliance.

- Detailed Data Logging: A critical component is the ability to monitor and record data for every weld. This creates a detailed record for quality control and traceability, proving that each component was manufactured to the required specification.

- Material and Joint Adaptability: These advanced tools are engineered to work with challenging materials like titanium and high-strength alloys, performing complex welds that would be difficult or impossible to achieve manually.

Applications Beyond the Hangar

The need for this level of precision extends far beyond building aircraft. The medical device industry, for instance, relies on microscopic, flawless welds for implants and surgical tools. In the energy sector, the integrity of pipelines and power plant components is paramount for public safety. Automotive manufacturers are also adopting aerospace-grade precision welding tools to work with new, lightweight alloys that improve fuel efficiency without compromising structural safety. In each of these fields, meeting stringent compliance standards is a baseline requirement, not just a goal.

A Focus on Engineering and Quality

At SEC Automation, our foundation is in engineering solutions to complex manufacturing challenges. We see automated welding as a critical tool for modern industry. Our work with AutonoWeld automated welding solutions is focused on implementing the principles of precision and repeatability inherent in aerospace-grade precision welding tools. We help our clients build more robust quality control systems into their production lines, ensuring their products are not only compliant but also built to the highest possible standard.

Discuss Your Needs for Aerospace-Grade Precision Welding Tools

If your work involves high-stakes applications where weld integrity is critical, you understand the challenges of maintaining quality and compliance. The technology and processes once reserved for aerospace are now accessible and essential for ensuring safety and performance in many fields.

If you’re exploring ways to improve your welding processes, we’d be happy to discuss how these advanced systems can apply to your specific needs. Contact our team at SEC Automation to learn more.